You’ll need a tune when installing long tube headers because they notably alter your engine’s exhaust flow behavior, shifting air-fuel ratios from the ideal 14.7:1 to potentially dangerous 15.5:1 or higher. Without proper ECU recalibration, you’ll experience check engine lights, poor drivability, and risk serious engine damage from lean conditions. The headers relocate oxygen sensors downstream, causing delayed feedback that misleads your ECU’s fuel delivery calculations. Professional tuning becomes essential to maximize the 5-20 horsepower gains while protecting your engine’s longevity and ensuring peak performance parameters.

Quick Tips

- Long tube headers alter exhaust flow dynamics, causing leaner air-fuel mixtures that require ECU recalibration for optimal performance.

- Running headers without tuning can cause engine damage from lean conditions, check engine lights, and increased emissions.

- Oxygen sensor relocation downstream affects ECU feedback response time, making proper calibration essential for accurate fuel management.

- ECU adaptive learning cannot compensate for major exhaust modifications, requiring professional tuning to maximize performance gains safely.

- Proper tuning prevents costly engine damage while delivering enhanced power output, improved drivability, and optimized fuel efficiency.

How Long Tube Headers Affect Engine Performance

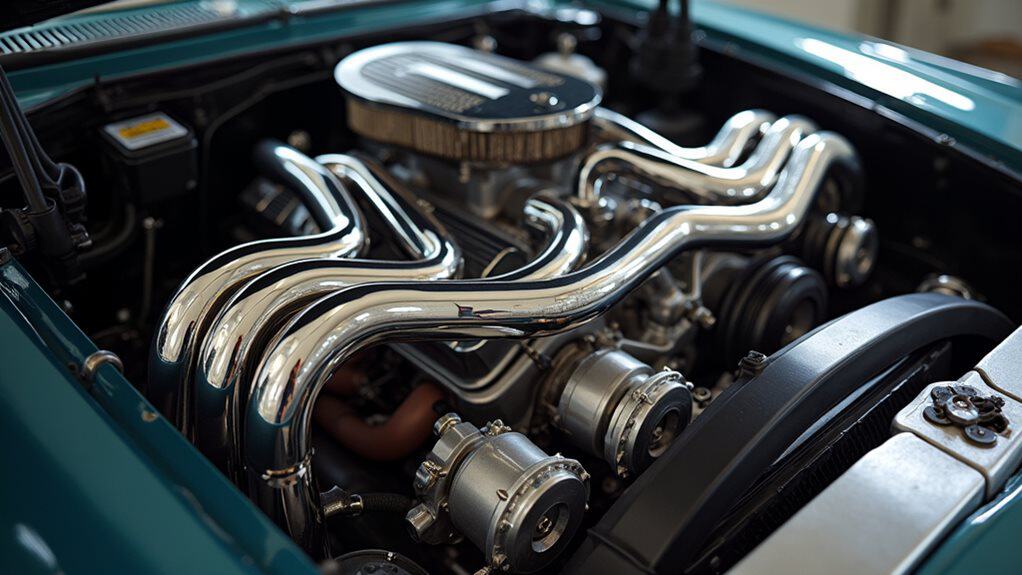

When you install long tube headers on your engine, you’re fundamentally changing how exhaust gases exit the combustion chambers and travel through the exhaust system.

The longer primary pipes reduce backpressure, allowing your engine to expel spent gases more efficiently. This improved scavenging effect enhances cylinder filling, typically providing 5-20 additional horsepower in mid-to-high RPM ranges. A well-designed performance camshaft can further amplify these gains by optimizing valve timing for better airflow.

These headers create standing waves that optimize exhaust extraction timing, with the wave dynamics helping pull exhaust gases from the cylinders more effectively than stock manifolds.

Understanding Air-Fuel Ratio Changes With Headers

When you install long tube headers, you’ll notice they create leaner air-fuel mixtures because the reduced backpressure allows more air to flow through your engine while the fuel delivery remains unchanged. This increased airflow can push your air-fuel ratio from the ideal 14.7:1 stoichiometric ratio to something like 15.5:1 or higher, which means there’s more air than fuel in the combustion chamber. Additionally, long tube headers relocate your oxygen sensors further downstream in the exhaust system, which can delay their response time and affect how accurately your engine’s computer reads the actual air-fuel mixture. It is important to monitor engine performance after installation, as changes may indicate the need for tuning adjustments. Modern vehicles with adaptive learning capabilities can sometimes compensate for these changes automatically, though individual results may vary.

Headers Create Lean Mixtures

Long tube headers fundamentally alter your engine’s air-fuel mixture by dramatically improving exhaust scavenging efficiency.

This enhanced scavenging pulls exhaust gases more effectively while introducing additional fresh air into the exhaust stream. Your oxygen sensors detect this extra air, causing the ECU to perceive a lean condition.

Without proper tuning, your engine runs leaner than ideal, potentially causing performance issues.

Oxygen Sensor Relocation Effects

Beyond the lean mixture issues that headers create, relocating oxygen sensors presents another significant challenge that requires careful attention.

Long tube headers force you to move your front O2 sensors downstream, which delays the signal reaching your ECU. This delay causes your engine’s computer to receive outdated air-fuel ratio data, resulting in improper fuel delivery adjustments.

The Role of ECU Calibration in Header Modifications

Your ECU must recalibrate air-fuel ratios, ignition timing, and variable valve timing to match the headers’ improved flow characteristics. Without proper calibration, you’ll experience check engine lights, poor drivability, and reduced performance gains from your modification investment. Additionally, regular maintenance of your vehicle’s oil and filter ensures that the engine runs smoothly, which can contribute to the overall efficiency of performance modifications like long tube headers.

Risks of Running Headers Without Proper Tuning

Understanding how your ECU struggles with header modifications reveals why proper tuning becomes necessary, but what happens when you skip this critical step?

You’ll face engine damage from lean air-fuel ratios, persistent check engine lights, decreased performance, and increased emissions.

Your engine runs hotter, knocks more frequently, and experiences accelerated wear without proper calibration. Additionally, irregular shifts in transmission performance can further exacerbate engine strain and lead to more serious issues down the line.

Vehicle-Specific Considerations for Header Installations

When selecting headers for your vehicle, you’ll uncover that fitment depends entirely on your specific year, make, model, and engine configuration.

Your drivetrain type affects routing requirements, while transmission differences influence clearance needs. You must verify engine mount condition since worn mounts shift positioning, causing interference.

Different chassis designs require specific collector orientations for proper exhaust system connections.

Oxygen Sensor Relocation and ECU Adjustments

When you install long tube headers, you’re moving the upstream oxygen sensors approximately six inches further from the engine compared to their stock manifold positions.

This relocation creates a signal transport delay that confuses your ECU’s fuel management system, since it now receives delayed feedback about exhaust gas composition.

Your engine’s computer needs specific recalibration adjustments to compensate for this new sensor distance, or you’ll experience poor throttle response and inefficient air-fuel ratios.

Sensor Position Changes

Installing long tube headers fundamentally changes where your engine’s oxygen sensors are positioned, creating a cascade of challenges that directly impact how your ECU monitors and controls the air-fuel mixture.

The sensors move farther from exhaust ports, experiencing cooler temperatures and delayed exhaust pulse readings. This relocation disrupts timing, causing inaccurate fuel trimming and potential drivability issues.

ECU Recalibration Requirements

The relocated oxygen sensors create a domino effect that forces your ECU to work with fundamentally different data inputs than it was originally programmed to handle.

Your engine control unit must receive updated software to correctly interpret these altered exhaust gas readings.

Without proper recalibration, your ECU can’t maintain accurate closed-loop fuel control, causing incorrect air-fuel mixtures.

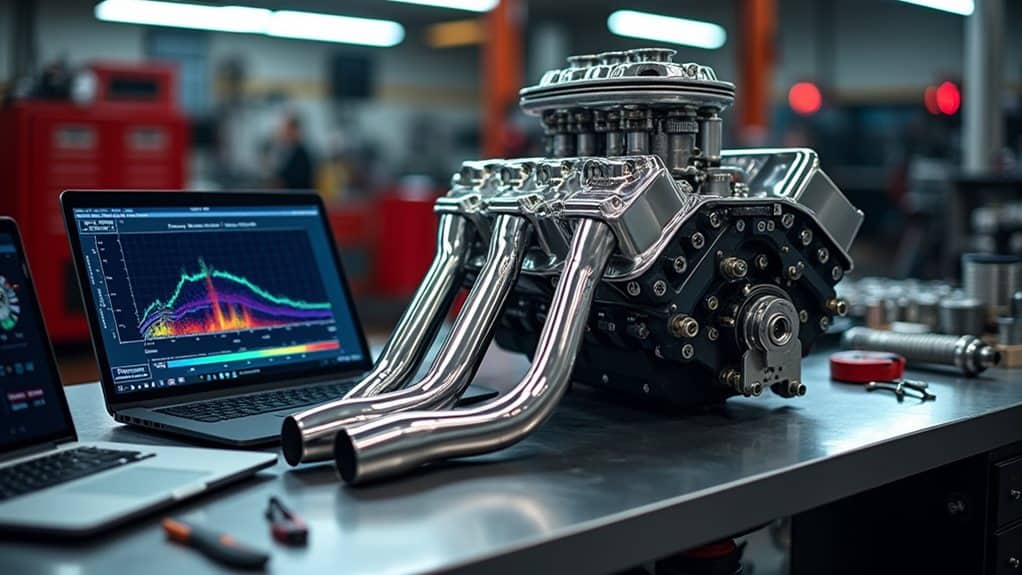

Performance Benefits of Professional Tuning

While long tube headers provide substantial exhaust flow improvements on their own, professional tuning unlocks their full potential by optimizing your engine’s computer-controlled parameters.

You’ll gain up to 30% more horsepower and torque through recalibrated fuel delivery and ignition timing.

Enhanced throttle response, improved fuel economy, and prevention of check engine lights guarantee maximum performance benefits.

Key Tuning Parameters Modified by Long Tube Headers

Once you install long tube headers, your engine’s computer must recalibrate several critical parameters to maintain peak performance and prevent operational issues.

Your ECU adjusts fuel injection timing, spark advance maps, and oxygen sensor delay compensation.

Additionally, variable valve timing settings, fuel trim corrections, and airflow calculations require modification to work properly with your headers’ improved exhaust scavenging.

Engine Longevity and Protection Through Proper Calibration

Beyond simply adjusting computer parameters, proper calibration after installing long tube headers directly impacts your engine’s lifespan and overall health.

Headers reduce exhaust back pressure, allowing your engine to breathe easier and operate with less strain. This decreased resistance lowers wear on piston rings and valves while improving fuel efficiency through optimized combustion and reduced heat buildup.

Expert Recommendations From the Automotive Community

According to seasoned mechanics and automotive engineers throughout the industry, installing long tube headers without proper ECU tuning represents one of the most common mistakes performance enthusiasts make.

Professional tuners consistently emphasize that adaptive ECU learning can’t compensate for major exhaust modifications. They strongly recommend thorough tuning to maximize performance gains while preventing costly engine damage from lean conditions.

Making the Decision: When Tuning Becomes Essential

While expert consensus clearly favors tuning, you’ll need to evaluate specific factors that determine whether your particular installation absolutely requires ECU recalibration.

Consider your vehicle’s adaptive learning capabilities, sensor relocation requirements, and performance goals.

If you’re experiencing check engine lights, poor drivability, or want maximum power gains, tuning becomes essential rather than optional.

Wrapping Up

You’ll need proper tuning after installing long tube headers to maintain ideal engine performance and prevent potential damage. While some vehicles may run acceptably without immediate calibration, you’re risking lean conditions, reduced power output, and long-term engine problems. The investment in professional tuning guarantees you’ll maximize your headers’ benefits while protecting your engine’s longevity. Don’t compromise your modification’s potential—get a proper tune for the best results.