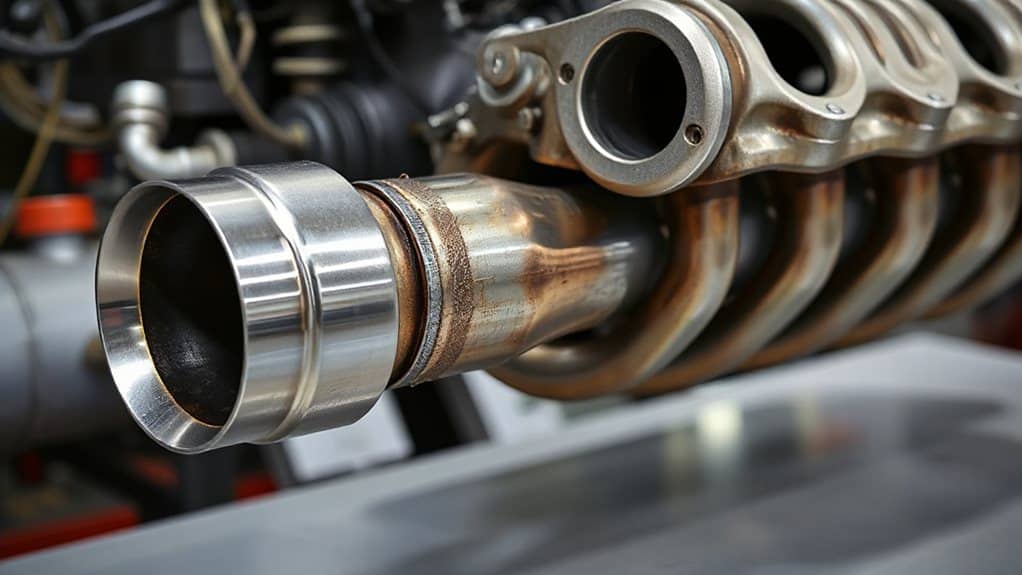

You bolt headers to your engine’s cylinder heads to improve exhaust flow right from the combustion chambers, especially on naturally aspirated engines. Downpipes, however, attach to the turbocharger’s outlet, directing exhaust gases away efficiently in turbocharged setups. Headers increase scavenging and high-end power; downpipes enhance turbo spool and mid-range response. Both need tuning, affect noise and emissions, and influence underhood heat. You’ll uncover how fitment and design impact performance and reliability as we go.

Quick Tips

- Headers connect to cylinder heads on all engines; downpipes attach only to turbocharged engines’ turbine outlets.

- Naturally aspirated engines use headers only, while turbo engines require both headers and downpipes.

- Headers improve exhaust scavenging; downpipes reduce back pressure and enhance turbo spool.

- Downpipes are typically easier to install; headers often require mid-pipe or custom fitment changes.

- Catless downpipes increase noise and emissions; catted versions help maintain legality and reduce sound.

Downpipe vs Header: Function and Placement Compared

While both downpipes and headers play crucial roles in a vehicle’s exhaust system, they serve different functions and occupy distinct positions depending on the engine type.

You’ll find headers bolted to cylinder heads in naturally aspirated engines, replacing manifolds to improve exhaust flow.

Downpipes, however, attach directly to the turbo’s turbine housing, channeling post-turbo gases through catalytic converters and sensors while reducing back pressure and emissions. Aftermarket downpipes significantly enhance exhaust gas movement, with increased exhaust flow being a key benefit for turbocharged performance. Proper placement also affects coolant flow direction in some engine bay layouts, which can influence thermal management.

Turbo vs NA: Which Engine Needs Which Part?

You already know that headers connect to the cylinder heads and help exhaust gases exit the engine more efficiently, while downpipes take over after the turbocharger, guiding gases toward the rest of the exhaust system.

If you have a turbo engine, you need both: headers to route exhaust to the turbo, and a downpipe to carry it from the turbo.

Naturally aspirated engines only use headers—no turbo means no downpipe needed.

The fuel system’s behavior can be affected by the Fuel Pump Control Module, which regulates power to the pump and maintains correct fuel pressure.

Horsepower and Torque: Performance Gains Side by Side

Release more power by understanding how headers and downpipes increase horsepower and torque in different ways.

You gain 10–20 hp with either; headers enhance scavenging, shifting power higher, while downpipes improve turbo spool and mid-range flow.

Both need a tune for full effect.

Headers amplify torque more in NA engines; downpipes excel in turbo setups, supporting up to 500 hp when tuned.

Proper professional tuning is recommended to prevent lean conditions and maximize gains by recalibrating the ECU and compensating for oxygen sensor relocation.

Noise and Emissions: Legal and Sound Differences

Because exhaust modifications directly impact both sound and emissions, choosing between headers and downpipes means balancing performance with legal and environmental considerations.

You’ll hear a raw, aggressive tone with catless downpipes or headers, while catted versions stay smoother and quieter.

Removing cats increases pollutants and noise, risking legal issues.

Catted setups keep emissions compliant, and exhaust valves help control volume legally.

Understanding warranty effects is important because some modifications can void warranties if they cause related damage.

Fitment: Downpipe vs Header Installation Realities

You’ll find downpipes much easier to install since they bolt on after the turbo without needing engine work.

Headers, though, connect right to the cylinder heads and often require you to modify or replace the mid-pipe—especially with long-tube versions. While shorty headers keep things simple, any header upgrade on a turbo car means you’ll need a custom connection to the turbo, adding time and complexity. An electric choke can affect cold-start drivability and may require adjustment when changing intake or exhaust components to maintain proper idle and warm-up behavior electric choke.

Turbo Integration Requirements

When upgrading your vehicle’s exhaust system, understanding how each component integrates with forced induction is critical, especially since downpipes and headers serve fundamentally different roles in turbocharged versus naturally aspirated engines.

You must pair downpipes with turbo systems—they connect the turbo’s outlet to the exhaust, reducing backpressure and improving spool.

Headers, however, feed exhaust from NA engines directly into manifolds.

Turbo setups need precise downpipe fitment to manage high-temperature gases and optimize scavenging, while headers on turbo engines demand custom fabrication, as bolt-on compatibility doesn’t exist.

Proper integration guarantees performance gains without flow restrictions or reversion issues.

Header Compatibility Variations

Now that you understand how downpipes and headers interact with turbocharged systems, it’s time to focus on where and how each part fits in real-world installations.

You’ll find headers bolt directly to the engine, replacing stock manifolds on most non-turbo vehicles. They work with turbo setups only if the turbo system is custom-built to connect afterward, limiting universal fit.

Exhaust Flow: How Design Affects Engine Cooling

Although exhaust system design is often discussed concerning horsepower and turbo response, the way exhaust gases flow through components like headers and downpipes also plays a role in engine cooling and thermal management.

Efficient flow reduces heat retention, while poorly designed sections can trap hot gases. This buildup raises underhood temperatures, affecting nearby components. Proper material choice and routing help dissipate heat, maintaining ideal engine operating conditions and preventing thermal stress over time. Monitoring exhaust gas temperature can provide early warning of issues that increase heat and risk engine damage.

Wrapping Up

You now understand that headers improve exhaust flow on naturally aspirated engines, while downpipes enhance turbo efficiency by reducing backpressure. Both increase horsepower and torque, but fitment and emissions compliance vary. You must consider local laws, as modified downpipes may fail emissions tests. Proper installation guarantees peak exhaust flow, aiding engine cooling. Choose based on your engine type and performance goals, keeping noise and regulations in mind.