P1326 on your Kia Optima means the ECM detected knock‑pattern vibrations, often from rod‑bearing wear, low oil pressure, or corrupted knock‑sensor signals, and a stuck glow relay can cause voltage surges or EMI that mimic or mask those signals; you’ll see MIL illumination, possible limp mode, rough idle or metallic knock, so inspect the sensor, wiring, grounds, relay operation, battery/alternator and oil condition promptly, and if you continue you’ll get step‑by‑step diagnostics and repair options.

Quick Tips

- P1326 means the ECM detected knock-pattern vibrations, often from rod‑bearing damage, triggering MIL and possible limp mode.

- A glow relay stuck ON can cause voltage surges or EMI that corrupt knock sensor signals and falsely set P1326.

- Symptoms include rough idle, hesitation, metallic knocking under load, reduced power, and occasional limp‑home operation.

- Diagnose by inspecting knock sensor and wiring, measuring sensor signals, testing the glow relay, and checking battery/charging health.

- Fixes range from wiring/relay repair and OEM sensor replacement to oil/rod‑bearing repairs and ECM software updates.

What the P1326 Code Indicates on a Kia Optima

Start by recognizing that the P1326 code on a Kia Optima signals the engine’s knock sensor detection system has found abnormal vibrations that match patterns of serious internal wear, most commonly connecting rod bearing damage.

You should know the ECM stores this code, lights the MIL, and may force limp mode; inspect knock sensor, wiring, oil pressure, and perform rod-bearing noise tests to confirm mechanical failure.

Check for applicable Service Campaign updates and wiring issues before replacing sensors.

Also consider inspecting cooling and lubrication systems for early signs of seal failure that could contribute to bearing damage.

How a Stuck Glow Relay Can Affect Knock Sensor Detection

You’ve already learned that a P1326 can point to serious mechanical wear detected by the knock sensor; however, electrical faults can mimic or cause the same symptoms, and a glow relay stuck ON is one of the offenders to take into account.

A stuck relay can create voltage surges, EMI, and wiring cross‑talk that corrupt knock sensor signals, trigger false P1326 codes, and confuse ECM diagnostics. Extended warranty programs and ECM software updates have been used by manufacturers to address related knock-sensor/ECM issues.

Regular inspection of related wiring and protective devices like fusible links can help identify and prevent electrical faults that may mimic or cause knock sensor issues.

Common Symptoms When P1326 and a Glow Relay Issue Occur

When P1326 appears alongside a glow relay that’s stuck ON, you’ll typically see a mix of electrical warning signs and engine-performance problems that point to both sensor confusion and possible mechanical wear; the Check Engine Light or MIL may illuminate or flash, the car can enter limp mode with reduced power and restricted RPMs, and drivers often notice rough idle, hesitation, or stalling during acceleration.

You’ll also hear metallic knocking, suffer reduced fuel economy, and face worsening symptoms under heavy load, often linked to low oil or bearing wear that persists until proper service is performed.

A failing alternator can contribute to these issues by causing insufficient voltage and electrical instability, which may exacerbate misfires and warning lights like Battery Warning Light appearing on the dash.

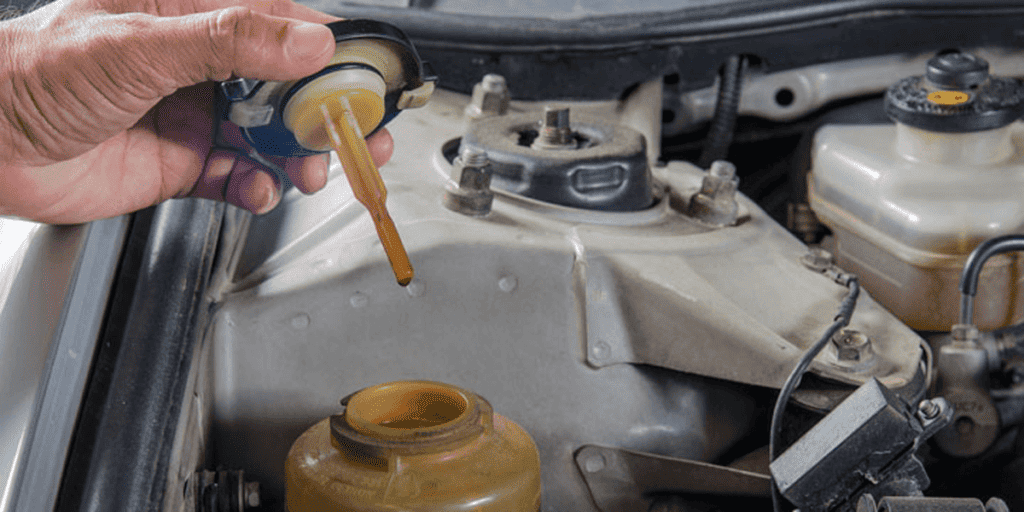

Diagnosing Knock Sensor, Wiring, and Relay Problems

Diagnosing knock sensor, wiring, and relay problems on a Kia Optima means combining targeted electrical tests with functional checks so you can pinpoint whether the sensor itself, its wiring/grounds, or a related relay is causing a P1326 or similar fault.

You’ll inspect connectors, measure sensor resistance and voltage, tap to elicit signals, check grounds, test relay operation with a multimeter, and scan ECM inputs for discrepancies.

Also verify the vehicle’s charging and starting systems by checking battery voltage and terminal condition to rule out battery-related issues that can mimic sensor or relay faults.

Repair Options: From Sensor Replacement to Engine Inspection

Start by considering repair options in a logical order, since addressing a P1326 code can range from a simple sensor swap to a full engine teardown depending on root cause and condition.

Replace faulty knock sensors with OEM parts, inspect wiring looms for shorts or opens, and check ECU updates. If knocking persists, measure rod bearing clearances and oil condition, then repair bearings or rebuild the engine as needed.

Preventive Maintenance to Avoid P1326 and Relay Failures

Because preventing a P1326 code and glow relay failures starts with routine care, you should establish a regular preventive-maintenance routine that targets the relay, glow plugs, wiring, and the engine control systems; inspect the relay and its connections every 12,000 miles (or annually), check fuses for corrosion, and look over the wiring loom for frays, loose contacts, or heat damage.

Also, test relay current, clean contacts, apply dielectric grease, monitor battery and alternator, replace glow plugs per schedule, install ECM updates, and protect components from moisture and debris to extend relay life and reduce faults.

Wrapping Up

You’ll want to treat a P1326 code and a stuck glow relay on your Kia Optima seriously but methodically; the code means the engine control unit is detecting abnormal knock signals, and a stuck relay can mask or mimic sensor faults by altering sensor power or grounding. Inspect the knock sensor, its wiring and connectors, and the relay function; replace faulty components, clear codes, then verify with a test drive. Regular checks prevent recurrence.