You’ll notice driveline symptoms like strong vibrations that grow with speed, loud clunks or knocks during acceleration, deceleration, or over bumps, and whining, grinding, or squeaking from dry splines; these point to worn or misaligned slip yoke splines, U-joint play, or poor lubrication. You may also feel steering bind, jerking under torque, or excessive axial play when the vehicle’s lifted, and you should inspect splines, grease fittings, and yokes for wear—keep going to learn fixes and diagnostics.

Quick Tips

- Severe driveline vibration that increases with speed, often from worn splines or imbalance at the slip yoke.

- Loud clunking or knocking during acceleration, deceleration, shifting, or over bumps indicating slip yoke play.

- Whining, grinding, or squeaking noises that worsen with torque, signaling dry or deteriorated slip yoke splines.

- Excessive axial or lateral play when the driveshaft is rocked, showing worn splines, loose bolts, or tailcone bushing wear.

- Difficulty turning, jerking, or uneven power delivery caused by binding or misalignment of the slip yoke and driveshaft.

Excessive Vibrations While Driving

Frequently, excessive vibrations while driving point to problems with the slip yoke and its related parts, and you should treat them as a mechanical warning rather than a minor annoyance.

You’ll feel shaking that grows with speed, often from worn splines, u-joints, imbalance, incorrect angles, or over-greasing causing binding.

Inspect splines, test play, check angles, and replace worn parts to restore smooth operation.

A failing slip yoke can interrupt torque transfer and stop the vehicle from moving, so have a technician inspect the driveshaft promptly.

Regular inspections and maintenance can catch issues early and help prevent drive system failures that lead to more extensive repairs.

Loud Clunking or Knocking Noises

If vibrations often signal worn splines or imbalanced components, loud clunking or knocking noises usually point more directly to play or binding at the slip yoke itself, and you should treat these sounds as a mechanical symptom that needs inspection.

You’ll hear distinct clunks when accelerating, decelerating, shifting or on bumps; check for worn splines, dried grease, excessive driveshaft play, and loose seating.

A broken driveshaft can cause sudden loss of control and requires immediate attention, so inspect the driveshaft components for damage.

Whining, Grinding, or Squeaking Sounds

Listen for whining, grinding, or squeaking coming from the driveshaft area, because these sounds often mean lubrication 부족 소리—dry splines or lost grease that let metal-on-metal 마찰음 occur.

You’ll notice the noise usually gets worse progressively as torque changes or speed increases, and that worsening pattern helps distinguish simple lack of grease from deeper spline or u-joint damage.

Check for visible wear, rust, or excessive play at the slip yoke and regrease the splines first; if the noise persists or metal scoring is present, plan for replacement rather than just more lubrication.

Cold temperatures can exacerbate lubrication loss and component wear, so inspect the slip yoke regularly during seasonal temperature changes.

Lubrication 부족 소리

Whining, grinding, or squeaking from a slip yoke usually points to insufficient lubrication, and you’ll often hear these noises change with throttle input or shifts in vehicle load.

You’ll notice dry splines and binding as grease disappears, causing increased friction, intermittent grinding, and vibration.

Check for blocked fittings, dirt contamination, or degraded lubricant; re-grease correctly, avoid overgreasing, and inspect for accelerated wear.

Metal-on-metal 마찰음

You’ll often hear metal-on-metal noises from the slip yoke—whining, grinding, or high-pitched squeaks—when the splines or adjacent components are worn, rusted, or poorly lubricated.

Whining suggests dry or corroded splines scraping seals during rotation, often under load.

Grinding means severe wear or pitting, needing immediate repair.

Squeaks point to binding or insufficient grease; re-lubricate, inspect for damage.

Progressive 소음 악화

When you hear progressive noises from the slip yoke—starting as faint whines, then developing into grinding or persistent squeaks—treat them as a clear sign that spline engagement and lubrication are deteriorating and require prompt inspection.

You should note when whining occurs during throttle changes, clean and regrease splines for squeaks, and address grinding immediately, since it signals abrasive wear or lost lubrication that can cause driveshaft failure.

Difficulty Turning or Driveability Problems

You may notice reduced steering responsiveness when a slip yoke or driveshaft is worn, meaning the wheel doesn’t react as quickly to your inputs and feels sluggish.

This happens because damaged splines or a misaligned yoke can interrupt torque transfer from the transmission to the wheels, causing binding or uneven power delivery, which makes turning less smooth.

Inspect for resistance or jerking during cornering, and if steering problems persist despite a healthy power steering system, treat the driveshaft and slip yoke as likely culprits requiring professional assessment.

Regular inspections can help catch related issues early, since components like wheel bearings and ball joints also affect steering feel and should be checked.

Reduced Steering Responsiveness

Often a gradual loss of steering responsiveness points to problems in the slip yoke or intermediate steering shaft, and you should treat it as a drivability concern rather than a minor annoyance.

You may feel play, delayed response, or a wobbly wheel from worn splines or U-joints; binding or stiffness can also occur from misalignment or lack of lubrication, degrading precise steering control.

Torque Transfer Issues

Inspect the slip yoke first if your vehicle feels hesitant or jerky during turns or when you accelerate, because the slip yoke is a primary path for torque from the transmission to the driveshaft and any wear or misalignment there directly disrupts power flow.

Excess play, binding, worn splines, or poor lubrication cause intermittent torque transfer, shuddering, jolts, and vibration, reducing acceleration smoothness and drivability.

Impaired Turning Smoothness

When the slip yoke is worn, misaligned, or poorly lubricated, you’ll notice turning feels less smooth and the vehicle may hesitate between your steering input and its response; this happens because the slip yoke is a primary connection that lets the transmission accommodate driveline length changes while the wheels turn, and any binding or excess play there directly alters how torque and rotation are transmitted.

You’ll feel resistance, vibrations, clunks, or jerks during turns indicating spline wear, misphase, or seized movements; inspect lubrication, spline engagement, and U‑joint condition to restore predictable steering and drivability.

Excessive Play or Poor Slip Yoke Engagement

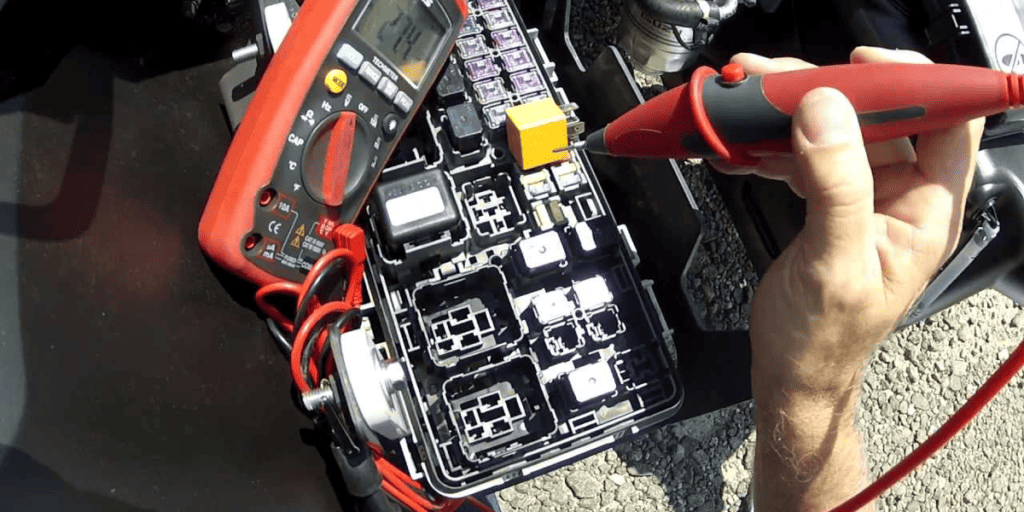

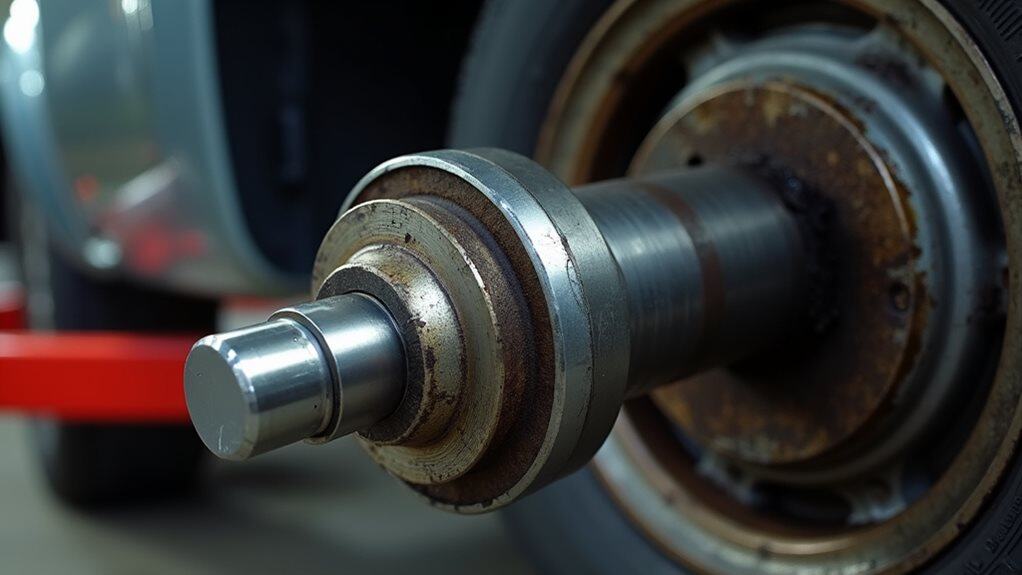

Check the slip yoke by wiggling the drive shaft while the vehicle is safely raised, because excessive play—movement between the output shaft and the yoke—directly affects driveline engagement and can produce vibrations, clunks, and uneven rotation.

If you detect vertical or horizontal movement, inspect splines, rear yoke bolts, U-joints and tailcone bushing to identify worn parts causing sloppy engagement.

Grease and Lubrication Issues

Greasing the slip yoke properly matters because inadequate or degraded lubricant directly causes noise, accelerated wear, and eventual driveline failure; you’ll hear whining, grinding, or squeaking and you may feel vibrations or clunks if the splines and sliding surfaces aren’t protected.

Check for rust, loss of grease, or seals pushed out; force fresh grease until it appears at the vent and seal, following manufacturer procedures.

Wrapping Up

You should address a bad slip yoke promptly, because it can cause vibrations, noises, steering issues, or loss of driveline engagement, each indicating wear, poor lubrication, or misalignment. Inspect for excessive play, torn seals, or contaminated grease, and check U-joints plus spline engagement; replace or re-grease parts per manufacturer specs. For safety and to prevent further damage, consult a qualified technician if you’re unsure, and follow recommended torque and service intervals.