When your air suspension won’t inflate, you’re likely dealing with damaged air bags that can’t hold pressure, leaking lines and fittings causing air loss, a faulty compressor unable to generate sufficient pressure, defective pressure sensors sending incorrect readings to the system’s computer, malfunctioning leveling controllers that can’t properly distribute air, or corroded wiring connections disrupting communication between components. Each issue requires specific diagnostic testing and targeted repairs to restore proper functionality and vehicle height control.

Quick Tips

- Check for air leaks in bags, lines, and fittings using soapy water to identify bubbles indicating pressure loss.

- Test compressor functionality as overworking or failure prevents proper system pressurization and height adjustment.

- Inspect electrical connections, relays, and wiring for corrosion or damage that disrupts communication between suspension components.

- Verify solenoid operation since faulty solenoids affect air distribution and prevent proper system inflation.

- Examine pressure sensors for accuracy as faulty sensors cause incorrect readings and improper air pressure control.

Low System Air Pressure Problems

When air suspension systems lose pressure, your vehicle’s ride quality and handling suffer considerably.

Air leaks from airbags, lines, or fittings cause gradual pressure loss and vehicle sagging. These leaks make your compressor work harder, cycling frequently to maintain pressure. Additionally, driveshaft failures can occur if the vehicle’s handling is compromised, leading to potential safety hazards.

Small leaks accumulate over time, requiring multiple inspections to identify. Improper air line routing creates rubbing damage, leading to additional pressure loss. Faulty pressure sensors can display incorrect readings even when no actual leaks exist, making diagnosis more challenging.

Compressor Failure and Performance Issues

Air pressure problems often stem from leaks, but the compressor itself can become the primary culprit behind suspension failures.

You’ll notice decreased ride quality, inability to adjust height, and unusual noises when your compressor malfunctions. Regular maintenance of battery and connections can help prevent electrical issues that may impact compressor performance.

Constant operation indicates overworking from damaged air springs, while electrical testing with lab scopes reveals motor performance degradation before complete failure occurs. Non-operational compressors may indicate burnout or electrical issues requiring immediate attention.

Air Leaks in Lines and Fittings

Several key components in your vehicle’s air suspension system serve as common failure points where leaks frequently develop. Manifold ports, airbag fittings, and air line connections deteriorate over time, causing pressure loss. You’ll notice sagging corners and excessive compressor operation. Spray soapy water on suspected areas to identify bubbles indicating exact leak locations, then replace damaged fittings. Regular visual inspections of connections and fittings can help prevent early alternator failure, ensuring your suspension system operates efficiently.

Faulty Pressure Sensors and Relays

Although air leaks represent one major source of suspension problems, electrical components like pressure sensors and relays create equally frustrating issues that can leave you scratching your head.

Faulty pressure sensors can’t accurately detect air pressure levels, causing improper inflation and triggering dashboard warning lights.

Meanwhile, defective relays prevent compressors from activating, stopping your system from inflating properly. Regular checks and maintenance of power steering fluid can also help prevent similar issues in other vehicle systems.

Defective Leveling Controller Signals

Beyond sensor and relay malfunctions, your air suspension system depends on proper communication between its leveling controller and various components to maintain correct vehicle height.

When the controller fails to send inflate or deflate signals, your suspension won’t respond properly.

You’ll notice uneven stance, error messages, and failed height adjustments requiring controller replacement.

Wiring and Electrical Connection Problems

When your air suspension system fails to operate properly, you’re often dealing with wiring and electrical connection problems that disrupt the communication between components.

Controller signal failures occur when the electronic control unit can’t send or receive the proper commands to activate compressors, solenoids, and valves due to voltage drops or corrupted data transmission.

Damaged wire connections create intermittent or complete electrical failures that prevent your suspension from inflating, deflating, or maintaining proper ride height.

Controller Signal Failures

Most air suspension problems stem from controller signal failures, which occur when the electronic control unit (ECU) can’t properly communicate with the system’s various components.

When your ECU malfunctions, it sends erratic signals to solenoid valves, causing inconsistent height adjustments.

Software glitches disrupt signal processing between sensors and actuators, while electrical component failures prevent proper solenoid valve activation.

Damaged Wire Connections

While electronic control unit failures create communication breakdowns, damaged wire connections represent the physical backbone problems that can cripple your air suspension system’s electrical network.

Poor grounding and loose connections cause voltage drops, preventing proper compressor operation. Corroded terminals disrupt communication between components, while exposed wiring near heat sources creates shorts that trigger dashboard warning lights.

Malfunctioning Air Valves and Distribution Systems

Air valves and distribution systems serve as the critical control mechanisms that regulate airflow throughout your vehicle’s suspension network. Their failure can quickly convert a smooth ride into a frustrating mechanical nightmare.

When these components malfunction, you’ll notice sticking valves preventing proper airflow, causing irregular ride height, backflow issues, and continuous compressor cycling.

Damaged Air Bags and Suspension Components

Although air valves create significant problems when they fail, damaged air bags and suspension components represent an even more serious threat to your vehicle’s air suspension system.

Rubber air bags develop tears from road debris, causing air leaks that prevent proper pressure maintenance.

You’ll notice sagging suspension, uneven vehicle height, and compromised handling when these components fail completely.

Diagnostic Testing Procedures

When your air suspension system fails, you’ll need to conduct systematic diagnostic testing to identify the root cause, starting with pressure testing methods that measure air volume and detect leaks throughout the system.

Electrical circuit diagnosis becomes equally important, as you must verify power supply to components like the ECU and compressor fuses, then test sensor outputs and communication networks between the control module and height sensors.

These two diagnostic approaches work together to pinpoint whether your suspension problems stem from air leaks, electrical faults, or component failures.

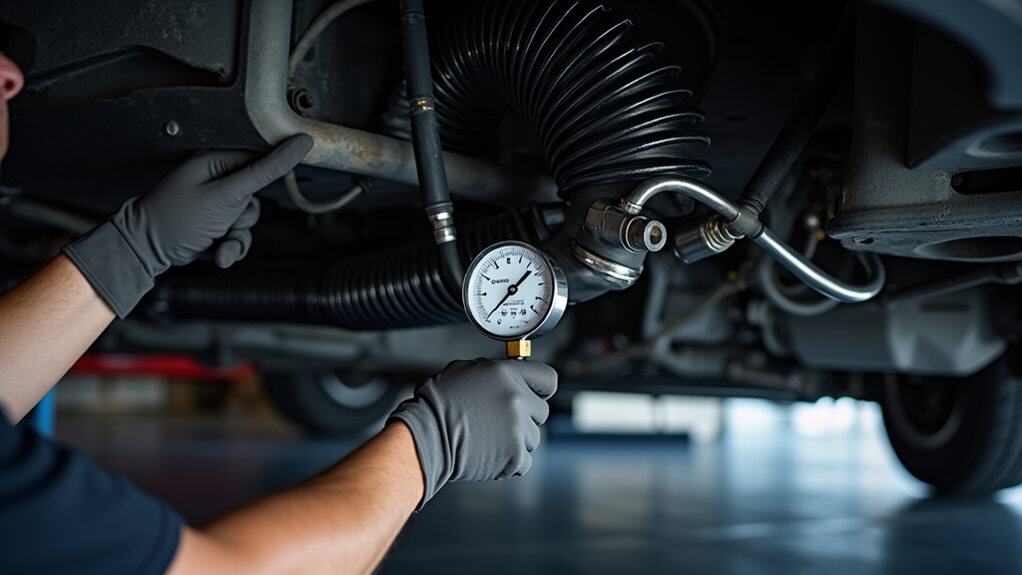

Pressure Testing Methods

Several diagnostic methods exist to evaluate the pressure integrity of air suspension systems, each serving specific purposes in identifying potential failures or weaknesses.

Pneumatic testing uses air pressure between 1.1 and 1.33 times design pressure, held for thirty minutes to detect leaks.

Gradual pressurization prevents material damage by increasing pressure in steps with initial leak checks.

Electrical Circuit Diagnosis

After confirming the air suspension system’s pressure integrity through testing methods, the next logical step involves examining the electrical circuits that control these pneumatic components.

You’ll need to conduct visual inspections of connections, check fuses, test the compressor relay, and verify sensor signals using diagnostic scan tools to isolate electrical faults effectively.

Troubleshooting With Proper Equipment

Because air suspension systems contain complex electronic and pneumatic components, proper diagnostic equipment becomes essential for accurate troubleshooting and efficient repairs.

You’ll need OBD-I test scanners for reading fault codes and testing solenoids automatically. Multimeters verify electrical continuity, while soapy water reveals air leaks through visible bubbles.

Vehicle lifting equipment provides safe access to components underneath.

Preventive Maintenance and Best Practices

While proper diagnostic equipment helps identify existing problems, implementing a thorough maintenance routine prevents most air suspension failures before they occur.

Inspect air bags, lines, and fittings weekly for damage or leaks. Clean components regularly, drain moisture twice yearly, and maintain proper tire pressure.

Check vehicle stance daily for uneven height, indicating potential issues.

Wrapping Up

You’ve now learned the primary causes behind air suspension failures and their corresponding solutions. When your system won’t air up, systematically check compressor operation, inspect for leaks, test sensors and relays, and examine controller signals. Don’t forget to evaluate air bag condition and suspension components. Regular diagnostic testing with proper equipment prevents costly repairs. Follow manufacturer maintenance schedules, and you’ll extend your air suspension’s lifespan while ensuring peak performance and safety.