You’ll get smoother, daily-friendly engagement with a Stage 1 clutch, thanks to its organic or carbon-Kevlar lining and stock-like pedal feel. It handles about 20–30% more torque than stock, making it ideal for mild upgrades. A Stage 2 clutch uses pure Kevlar with steel backing, offering higher clamp pressure and up to 110% more holding power for tuned or track-driven cars. It lasts longer under heavy use but requires a firmer pedal and proper break-in. There’s more to how materials and design shape performance.

Quick Tips

- Stage 1 offers smooth, stock-like engagement ideal for daily driving; Stage 2 provides firmer engagement suited for aggressive or track use.

- Stage 1 handles 20–30% more torque than stock; Stage 2 supports up to 110% more, ideal for tuned or upgraded engines.

- Stage 1 uses organic or carbon-kevlar linings; Stage 2 uses pure Kevlar with steel backing for higher durability and heat resistance.

- Stage 1 requires ~500-mile break-in; Stage 2 needs ~1,000 miles to properly seat the Kevlar friction surface.

- Stage 1 prioritizes drivability and comfort; Stage 2 trades some comfort for increased clamp load, torque capacity, and longevity.

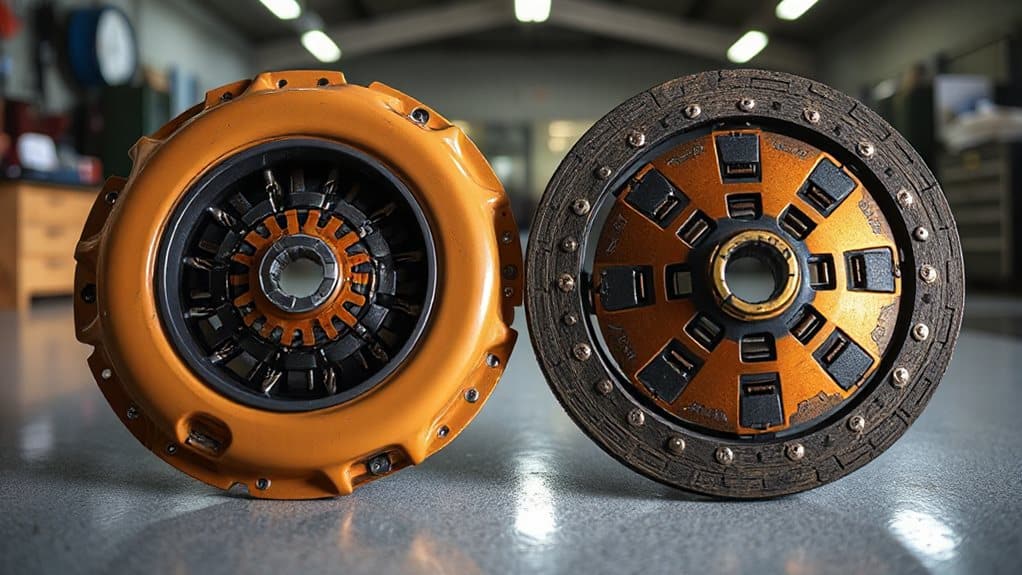

Clutch Stage 1 Vs Stage 2: Key Differences

While both Clutch Stage 1 and Stage 2 are built for performance, they differ markedly in design and function, so choosing the right one depends on your driving needs.

Stage 1 uses organic, carbon-kevlar lining for smooth engagement and daily drivability.

Stage 2 features pure Kevlar with steel backing, offering higher clamp pressure, heat resistance, and torque capacity—ideal for aggressive driving or track use.

This design provides slightly longer life compared to Stage 1, making it more durable under heavy use.

Also consider inspecting and lubricating pedal pivot points to ensure smooth operation and prevent noises from affecting clutch feel pedal pivot lubrication.

How Much Torque Can Each Clutch Handle?

You’ll want to know how much torque your clutch can handle, especially if you’re increasing your engine’s power.

A Stage 1 clutch manages about 20–30% more torque than stock, using reinforced organic or copper Kevlar materials and a stronger pressure plate for daily driving with mild upgrades.

In contrast, a Stage 2 clutch delivers up to 110% more holding power with full-face Kevlar and a dual clamp load design, making it ideal for serious bolt-ons like turbos or power adders.

Regular inspections and maintenance can prevent related issues such as starter motor failure that may cause expensive engine damage.

Torque Capacity Overview

Choose the right clutch stage, and you’ll match your engine’s upgraded power without sacrificing reliability or drivability.

Stage 1 handles up to 30% more torque than stock, using organic materials for smooth engagement.

Stage 2 doubles that capacity with Kevlar, supporting 50% power gains.

Stage 2+ bridges the gap with hybrid materials, offering 15–20% more torque handling than Stage 2—ideal for tuned street and track use.

Stage 1 Limits

A Stage 1 clutch typically handles around 30% more torque than stock, making it a solid upgrade for drivers who want improved performance without sacrificing daily drivability.

You’ll see clamping force rise 40% over OEM, with organic discs handling 300–540 lb-ft depending on brand.

Break in matters—follow the 500-mile period.

Dyno readings overestimate, so factor in 15–25% loss for real-world accuracy.

Stage 2 Strength

Stage 1 clutches offer a noticeable step up from stock for daily-driven performance vehicles, but once modifications push torque beyond that threshold, a stronger solution becomes necessary.

You’ll find Stage 2 clutches built to handle more—like the SPEC LS2 CTS-V, rated at 690 ft/lbs, or the Competition Clutch with up to 80% more capacity than stock. These use reinforced materials, higher clamp loads, and durable disc designs so you can confidently run aggressive street or light track power without slipping.

Organic Vs Kevlar: Clutch Material Compared

When it comes to picking the right clutch material, understanding the core differences between organic and Kevlar compounds is key.

Organic clutches offer smooth engagement and daily comfort but wear faster under heat.

Kevlar handles high temperatures and lasts longer, yet needs a strong pressure plate, breaks in slowly, and chatters at low speeds.

Choose organic for commuting, Kevlar for track-focused durability.

Also consider that vehicles with rear-wheel drive configurations may require more cautious clutch use due to traction and control differences.

Pressure Plate Upgrades: What Changes Between Stages?

You’ll notice the Stage 1 pressure plate uses a single diaphragm design with heat-treated springs to deliver 70% more clamp load than stock, yet still feels familiar at the pedal.

When you step up to Stage 2, the same basic structure gets reinforced for higher burst strength and pairs with a steel-backed Kevlar disc, increasing torque capacity without drastically changing pedal effort.

While both stages keep daily driving comfortable, the Stage 2’s optimized clamping force handles moderate power upgrades better, especially when combined with performance-oriented variants like the 2R.

Proper installation also requires following a multi-stage torque sequence and using Red Loctite on critical bolts to ensure secure fastening, particularly for flexplate bolts.

Clamp Load Comparison

While both Stage 1 and Stage 2 clutches increase torque capacity beyond stock, the key difference in clamp load isn’t found in the pressure plate’s clamping force but in how the disc material uses that force.

Stage 1 uses organic facings with slightly higher clamp load for up to 50whp gains.

Stage 2 keeps similar clamp pressure but pairs it with high-friction Kevlar discs, handling 50–75% more torque.

Pressure Plate Design

The clamp load discussion highlights how friction materials influence torque capacity, but the pressure plate itself plays a key role in providing that performance.

You’ll find both Stage 1 and Stage 2 use a single diaphragm design with heavy-duty straps for durability.

Stage 1 relies on reinforced organic facings, while Stage 2 shifts to steel-backed Kevlar for better heat resistance and wear life—ideal for track use—without altering the core pressure plate structure.

Daily Driving Feel: Stage 1 Vs Stage 2 Pedal & Engagement

Although both Stage 1 and Stage 2 clutches are designed for daily driving, they differ slightly in pedal feel and engagement due to their internal materials and construction.

You’ll notice Stage 1 offers stock-like smoothness with organic friction, while Stage 2 uses Kevlar for stronger grip without harshness.

Both maintain manageable modulation, OEM-like pedal effort, and progressive engagement—ideal for street use.

Over time, inadequate maintenance can lead to issues like deteriorated seals that affect clutch and related hydraulic component performance.

Best Use Cases: When to Choose Stage 1 Or Stage 2

When it comes to picking the right clutch for your modified vehicle, figuring out whether you need a Stage 1 or Stage 2 often comes down to how much power your engine makes and how you plan to use the car.

Choose Stage 1 for light mods and daily driving with smooth engagement.

Opt for Stage 2 if you’ve increased torque over 30%, track your car, or want stronger, longer-lasting performance.

Be mindful that improper driving techniques like excessive clutch slipping can lead to overheating and premature clutch failure.

Break-In And Lifespan: What to Expect

You’ve picked your clutch based on power and driving style—now it’s time to focus on how you treat it right after installation, because break-in directly shapes how long and how well it performs.

For Stage 1, drive 500 miles gently: keep RPMs under 4,500, use half throttle, and shift smoothly.

Stage 2 needs 1,000 miles; its Kevlar facing requires more time to seat properly.

Avoid hard launches, rapid acceleration, and aggressive downshifting in both.

Proper break-in guarantees even friction surface wear, maximizes holding power, and extends lifespan.

Skip it, and you risk slippage, shuddering, or premature failure.

Clutch Stage 1: Design And Limitations

Because your driving demands a balance between performance and daily usability, the Stage 1 clutch is engineered to upgrade your stock setup without compromising comfort.

It uses molded organic linings with steel backing for smooth engagement and increased heat resistance. The lightweight alloy pressure plate enhances clamping force by 40%, improving torque capacity while maintaining drivability, ideal for daily drivers with mild modifications.

Clutch Stage 2: Strengths And Trade-Offs

The Stage 2 clutch builds on the foundation of the Stage 1 by stepping up durability and torque handling without sacrificing all-day drivability.

You get a Kevlar friction disc with steel backing, increasing torque capacity to around 465 lb-ft. It lasts longer than organic discs, resists wear, and stays smooth in daily driving.

While pedal effort is heavier and engagement firmer, it remains street-friendly.

Installation is labor-intensive and costly, so it’s best suited for tuned or moderately upgraded engines, not stock ones.

Wrapping Up

You now know the core differences between Stage 1 and Stage 2 clutches. Stage 1 uses organic material, suits daily driving, and handles moderate power. Stage 2 uses Kevlar or ceramic, handles more torque, and has a firmer pedal. It’s better for performance use but less comfortable daily. Choose Stage 1 for reliability and smooth engagement; pick Stage 2 when you need durability under high stress.