P0847 on a Honda Fit means the transmission control module is seeing an abnormally low signal from the Transmission Fluid Pressure Sensor B circuit, which monitors hydraulic pressure in the valve body. You’ll want to check the sensor, wiring and connector for corrosion or breaks, verify the 5V reference and ground with a multimeter, and inspect ATF level and condition; common fixes are cleaning/repairing wiring or replacing the sensor, and more details follow if you keep going.

Quick Tips

- P0847 means low or no signal from the transmission fluid pressure sensor/switch “B” circuit on the Honda Fit.

- Common symptoms include transmission warning light, limp mode, harsh or delayed shifts, slipping, and intermittent drive loss.

- Causes include a faulty pressure sensor, damaged wiring/connector corrosion, low/contaminated ATF, or leaking hydraulic seals.

- Diagnose by reading codes with a scan tool, inspecting wiring/connectors, checking 5V reference/ground/signal with a multimeter, and verifying ATF pressure.

- Fixes range from cleaning/repairing wiring and connectors to replacing the TFPS or repairing internal leaks; retest with a scan tool after repair.

What P0847 Means for Your Honda Fit

P0847 flags a low signal in the Transmission Fluid Pressure Sensor/Switch “B” circuit, which means the control module is seeing pressure readings that are below the expected range for that particular sensor circuit.

You should know it points to a specific sensor fault, wiring damage, low or contaminated ATF, or moisture-related sensor failure; the sensor sits on the valve body and monitors hydraulic pressure.

Connection failure to server for this app or website at this time CloudFront distribution configured to block access from the country.

A failing seal in related hydraulic components can allow fluid to escape through a weep hole, indicating a potential pump or housing issue.

Common Symptoms to Watch For

When the transmission fluid pressure sensor/switch “B” circuit reports low readings, you’ll usually notice a mix of dashboard warnings and drivability problems that point toward hydraulic pressure issues.

You’ll see check engine or transmission lights, possible limp mode, slipping or harsh shifts, delayed engagement, reduced fuel economy, and overheating.

Inspect for erratic warning flashes, jerky gear changes, loss of drive, or intermittent sensor responses. In many cases the root cause is an electrical or sensor fault such as a faulty transmission fluid pressure sensor. Additional causes can include low fluid, internal transmission wear, or compromised seals that lead to reduced hydraulic pressure.

Typical Causes Behind the Code

When your Fit throws a transmission pressure sensor circuit code, it usually points to a sensor circuit failure or problems with the connector and wiring, so you’ll want to inspect both the sensor electronics and the electrical path that carries its signal.

Check the sensor itself for internal faults or moisture-vulnerable vent designs that can cause low-voltage readings, and then examine connectors and wiring looms for corrosion, loose terminals, rubbed-through insulation, or melted wiring that can create intermittent or shorted circuits.

Addressing the specific cause—cleaning and greasing connectors, repairing or replacing damaged wires, or fitting the updated sensor part—will restore proper signal integrity and stop the code from returning.

Regular inspection of protective components like fusible links can help prevent failures caused by overloads or damaged wiring.

Sensor Circuit Failure

If a transmission pressure sensor circuit fails, you’ll usually see it because the sensor or its associated systems can’t send a reliable voltage signal to the vehicle’s control modules, and that unreliable signal makes the PCM/TCM flag a fault.

Contaminated or low fluid, a failed TFPS, degraded sensor terminals, poor grounds or faulty fuses/relays can all corrupt voltage, requiring cleaning, fluid service, or sensor replacement.

Connector or Wiring Issues

Connector and wiring faults are a common root cause of a P0847 code, and you’ll often find that simple corrosion, poor fitment, or physical damage breaks the sensor’s ability to send a stable voltage signal to the PCM/TCM.

Inspect connectors for green corrosion, burned plastic, loose terminals, and moisture intrusion; clean with contact cleaner, brush, apply grease, then test voltage and continuity with a DVM.

How Technicians Diagnose P0847

Start by confirming the P0847 code with an advanced OBD-II scanner and noting any related transmission warnings, because accurate initial data steers every subsequent step; you’ll document whether the warning light is steady or intermittent and ride the vehicle to try to reproduce the symptom under load.

Then review Honda TSBs, inspect sensor accessibility, use pressure gauges and wiring diagrams, and validate faults before replacing parts.

Motorcraft oil filters are OEM-quality parts produced at a facility in Fayetteville, North Carolina with components tested for performance and reliability, which can be relevant when considering replacement parts for maintenance related to transmission servicing and fluid contamination checks involving oil and filter condition — see Fayetteville, North Carolina.

Step-by-Step Sensor and Wiring Checks

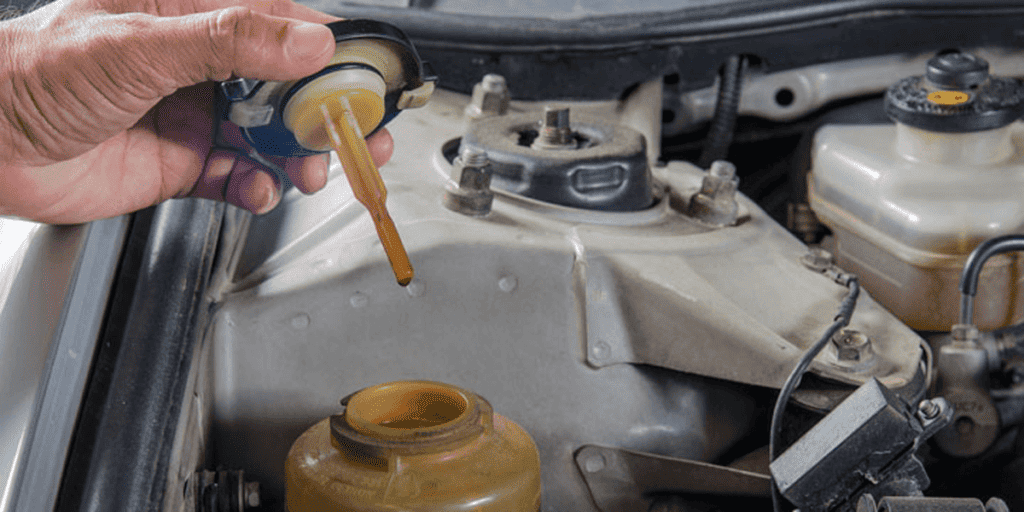

Before you touch any wiring, walk around the transmission to locate the transmission fluid pressure sensor B and visually map its connector, cable routing, and mounting so you know exactly what you’ll be testing and why.

Inspect connector for cracks, corrosion, and green tint; check wiring loom for chafing or heat damage.

Use contact cleaner, dielectric grease, and a multimeter to verify 5V reference, ground, and signal continuity.

Repair and Replacement Options

When you’re ready to fix a P0847 fault, you’ll choose between replacing the transmission fluid pressure switch itself or addressing the electrical system that feeds it, because most failures stem from wiring or connector problems rather than the sensor.

Inspect connectors, clean corrosion, test continuity, and only replace the switch if faulty; use correct tools, torque (~14–15 ft‑lb), then verify with a scan tool.

Cost Estimates and Parts Information

Several specific cost factors affect how much you’ll pay to diagnose and repair a P0847 on a Honda Fit, so understanding parts, labor, and diagnostic fees helps you budget correctly.

Expect OEM pressure switch retail prices near $50–$60, labor around $73–$107 (1–2 hours), and diagnostics $122–$179.

Vehicle speed or crank sensors run higher; proper tools and OEM parts reduce repeat failures.

Preventive Maintenance to Reduce Recurrence

Because loose or corroded wiring is a common cause of P0847, you should make connector and sensor checks part of routine maintenance so small issues don’t become repeated faults.

Inspect terminals for corrosion or heat damage, clean with contact cleaner, apply dielectric grease, secure wire looms, and scan for codes.

Replace redesigned TFPS parts when warranted, test wiring with a DVM, and document values.

Wrapping Up

You should treat P0847 as a clear signal that the transmission fluid pressure sensor circuit on your Honda Fit needs inspection and possible repair. Check wiring and connectors first, then test or replace the pressure sensor if readings are out of range, since incorrect data can impair shift quality and cause further wear. Costs vary with parts and labor, so get diagnostic confirmation before replacing components. Regular fluid and filter maintenance lowers recurrence risk.