When your check engine light shows code P0491, it means your vehicle’s secondary air injection system isn’t supplying enough airflow to Bank 1 of the engine. This emissions control system helps reduce harmful pollutants during cold starts by pumping fresh air into your exhaust system. Common symptoms include rough idling, unusual noises from the air pump, and sluggish acceleration. While repair costs typically range from $2,000-$3,000, understanding the underlying causes can help you make informed maintenance decisions.

Quick Tips

- The P0491 code indicates a malfunction in the secondary air injection system’s Bank 1, affecting emissions reduction during engine warm-up.

- The system’s insufficient flow means inadequate air delivery to the exhaust system, leading to increased emissions and poor engine performance.

- Common symptoms include check engine light illumination, rough idling, unusual noises from the air pump, and sluggish acceleration.

- Main causes include damaged air pumps, faulty solenoid valves, cracked hoses, electrical issues, and maintenance neglect.

- Without timely repairs, vehicles risk poor performance, increased emissions, potential engine damage, and costly repairs ranging from $2,000-$3,000.

Understanding the P0491 Code and Its Significance

When your vehicle’s check engine light illuminates with the P0491 code, you’re dealing with a specific issue in your secondary air injection system’s Bank 1.

This system’s primary function is to reduce harmful emissions by injecting fresh air into your exhaust system during engine warm-up. Regular inspections of the air injection system are vital to ensure its proper functioning and prevent emissions-related issues. While it won’t immediately affect your car’s performance, you’ll need to address it to maintain emissions compliance. When this system malfunctions, the vehicle’s computer detects insufficient airflow patterns for an extended duration.

Common Symptoms and Warning Signs

As your vehicle exhibits signs of a P0491 code, several distinct symptoms can alert you to secondary air injection system problems.

You’ll likely notice your check engine light illuminated, along with rough idling or stalling, especially during cold starts. Overheating risks can also be a concern if the secondary air injection system is not functioning properly.

Watch for unusual noises from the air pump, sluggish acceleration, and hissing sounds that could indicate vacuum leaks.

These symptoms often accompany reduced engine efficiency and increased emissions.

European vehicle owners, particularly those with Audi or BMW models, should be especially vigilant of these warning signs.

Essential Components of Secondary Air Injection Systems

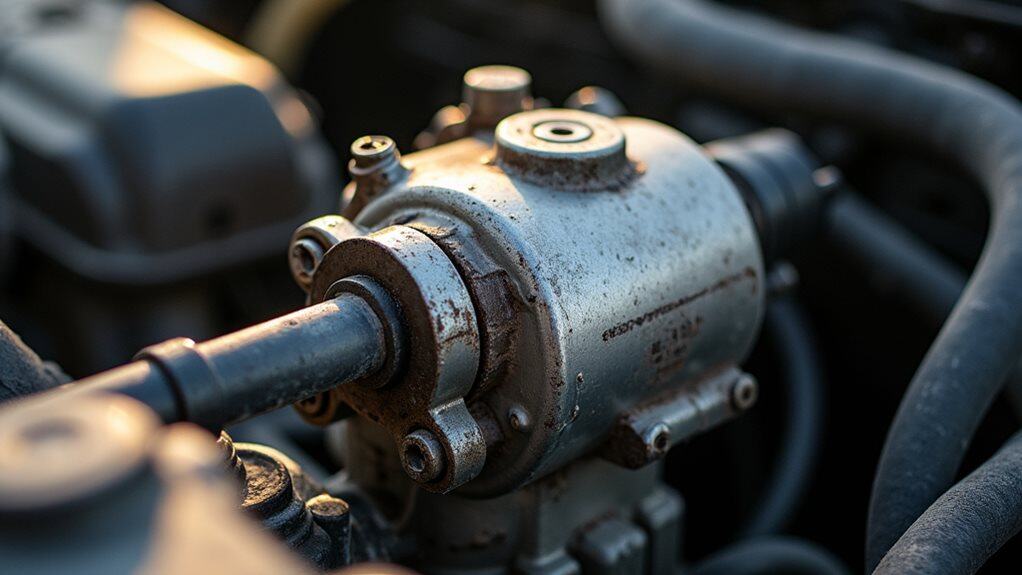

The secondary air injection system relies on several critical components working in harmony to reduce emissions during cold starts.

You’ll find an air pump that supplies pressurized air, solenoid valves that control airflow, and pressure sensors that monitor system operation.

These work alongside check valves that prevent exhaust backflow and a control relay that manages the system’s timing during cold starts. Additionally, the system’s efficiency can be affected by issues in the charging system that influence the power supply to these components.

Primary Causes of Insufficient Air Flow

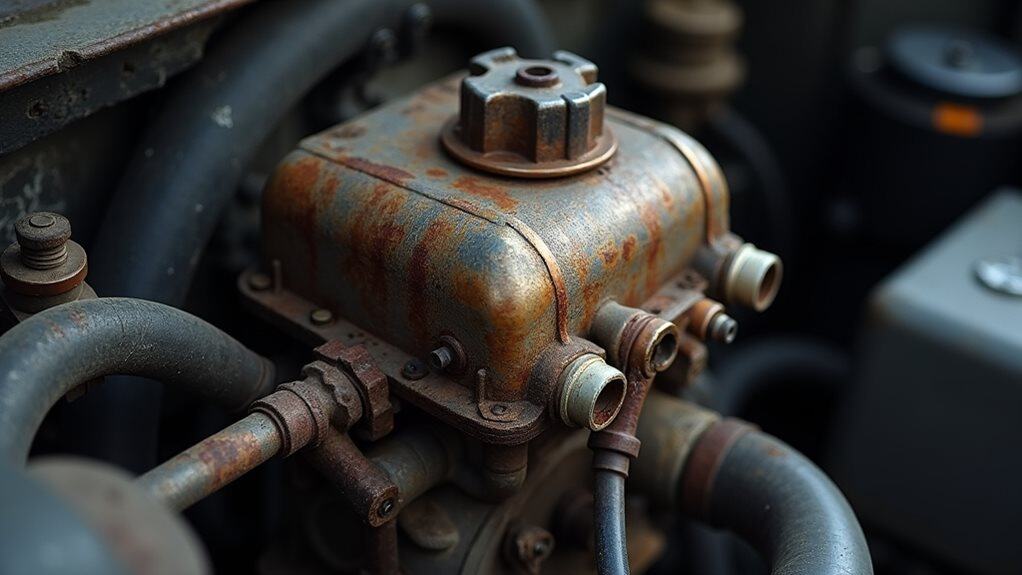

Secondary air injection systems commonly fail due to five major categories of problems that can considerably reduce airflow efficiency.

These include mechanical failures like damaged air pumps and clogged ports, electrical issues affecting relays and wiring, system leaks through cracked hoses, environmental factors such as moisture accumulation, and maintenance neglect leading to component deterioration. Additionally, increased oil consumption from engine problems can exacerbate the inefficiency of secondary air injection systems.

Diagnostic Steps to Identify the Problem

You’ll start your diagnostic process with a thorough visual inspection of all secondary air injection components, checking for obvious damage, disconnections, or deterioration that could affect system performance.

Next, you’ll need to test the electrical system using a multimeter to verify proper voltage at the air pump, relays, and control solenoids while documenting any irregularities or intermittent failures.

Finally, you’ll measure actual airflow using specialized diagnostic equipment to compare readings against manufacturer specifications, which will help pinpoint whether the issue stems from mechanical restrictions or electrical control problems.

Visual Component Inspection Process

Performing a thorough visual inspection of your vehicle’s secondary air injection system requires a systematic approach that’ll help identify potential issues before they become major problems.

Begin by checking all hoses and fittings for damage or wear, then inspect the pump’s physical condition.

Next, verify that check valves and switching valves are functioning correctly, and ascertain all electrical connections, relays, and fuses are secure.

Electrical System Testing Steps

When diagnosing electrical issues in your vehicle’s secondary air injection system, following a systematic testing procedure will help pinpoint the root cause of insufficient flow problems.

Begin by using your digital multimeter to check voltage at the air pump’s power and ground connections.

Then, test the relay’s control circuit and verify continuity through all related wiring using your wiring diagram as a reference.

Air Flow Measurement Methods

Accurate diagnosis of secondary air injection flow problems starts with proper measurement of system airflow using specialized diagnostic tools and techniques.

You’ll need to employ a scan tool to check MAF sensor readings and voltage outputs.

For precise measurements, perform both snap throttle and wide-open throttle tests while monitoring the sensor’s response to sudden airflow changes in real-world conditions.

Impact on Vehicle Performance and Emissions

A malfunctioning secondary air injection system greatly impacts both your vehicle’s performance and its emissions output.

You’ll notice your check engine light illuminating and possibly experience rough idling, especially during cold starts. Your vehicle’s acceleration may become sluggish, and you might hear unusual noises from the air pump.

Additionally, you’ll likely face emissions test failures due to increased pollutants like carbon monoxide and hydrocarbons.

Repair Options and Cost Considerations

When facing a Secondary Air Injection System repair, you’ll need to choose between a professional fix at a dealership, which typically costs $2,000-$3,000, or tackling the repair yourself with a bypass kit starting at $155.

DIY installations can save you significant labor costs, but you’ll need to assess your technical skills and comfort level with automotive repairs before proceeding.

If you’re not confident with vehicle repairs, professional installation might be worth the extra expense, especially for complex bypass kits that require soldering or tapping into the factory wiring.

DIY Vs Professional Repairs

Making an informed decision between DIY and professional repairs for your Secondary Air Injection System requires careful consideration of several factors, including your mechanical skill, available tools, and budget constraints.

While DIY repairs can save money and provide worthwhile experience, professional repairs offer knowledge, specialized tools, and warranties that may justify the higher cost, especially for complex issues that require advanced diagnostic equipment.

Parts and Labor Costs

Understanding the costs associated with Secondary Air Injection System repairs requires careful consideration of both parts and labor expenses.

You’ll need to budget around $374 for an Air Injection Control Valve, plus $170-$215 in labor.

For the complete system, costs vary considerably by vehicle model – from $98 for a Nissan Frontier to $1,475 for a Toyota Tundra.

Preventive Maintenance Strategies

Since proper maintenance of your Secondary Air Injection System (SAIS) can prevent costly repairs, implementing an extensive preventive maintenance strategy is essential.

You’ll want to schedule regular inspections for wear and damage, clean carbon buildup from intake passages, and check electrical circuits routinely.

Consider installing a uni filter mod and ensuring water protection measures are in place to extend your system’s lifespan.

Safety Implications of Delayed Repairs

When you delay repairs to your Secondary Air Injection System, you’re exposing yourself and others to significant safety risks that extend far beyond simple mechanical concerns.

Your vehicle may stall unexpectedly, especially during cold starts or while under load.

The insufficient airflow can lead to reduced engine performance, increased emissions, and potential engine damage through carbon buildup, compromising your safety on the road.

Long-Term Effects on Engine Health

As your vehicle’s Secondary Air Injection System continues to operate with insufficient flow, it’ll steadily deteriorate your engine’s overall health through a cascade of interconnected problems.

You’ll notice reduced fuel efficiency, rough idling, and sluggish acceleration.

Over time, your engine’s valve system and catalytic converter will suffer damage, while your air pump faces increased strain, potentially leading to more extensive and costly repairs.

Wrapping Up

If you’re dealing with a secondary air injection system insufficient flow in Bank 1, don’t delay addressing the issue. While you can continue driving briefly, this problem affects your vehicle’s emissions and engine performance. Schedule a diagnostic test with your mechanic, who’ll check for blockages, leaks, or failing components. Regular maintenance of your air injection system will help prevent these issues and extend your engine’s lifespan.