“Service Ride Control” means your vehicle detected a fault in the suspension control system and has limited automatic ride functions to protect components; it usually points to the air compressor, air springs (airbags), height sensors, valves, wiring, or fuses, and causes sagging, uneven ride, or a harsher feel. You should check fuses, inspect wiring and connectors, listen for continuous compressor operation, and scan for diagnostic trouble codes, and below you’ll find detailed diagnostic and repair steps.

Quick Tips

- “Service Ride Control” warns of a fault in the vehicle’s suspension control system, disabling some automatic ride functions.

- It indicates irregular sensor readings or lost communication between the suspension ECU, compressor, or height sensors.

- Common causes include compressor failure, leaking air springs/lines, blown fuses, corroded connectors, or faulty height sensors.

- Symptoms include a harsh or sagging ride, uneven corner height, constant compressor running, and a dashboard warning light.

- Diagnose with scan tools, check fuses/wiring, test compressor current and leaks, and seek professional repair for complex or persistent faults.

What “service Ride Control” Indicates on Your Dashboard

A dashboard message saying “Service Ride Control” tells you the vehicle’s ride control system has detected a fault in the suspension management equipment and has limited or disabled certain automatic functions; specifically, it means the suspension control processor has identified irregular readings or a loss of communication in components such as the air compressor, air springs (airbags), shock absorbers, sensors, or related wiring and fuses.

You should check codes, fuses, wiring, and compressor operation. Repair shops can perform a full diagnostic if needed. Mechanical inspection of components like shocks and height sensors can reveal common causes of the warning, so have the ride control system evaluated.

How Air Suspension Systems Work

Explaining how air suspension systems work will help you understand why your vehicle can raise, lower, or firm its ride automatically and what might trigger a “Service Ride Control” message.

Air springs use reinforced rubber bellows filled with compressed air, controlled by an ECU that reads height sensors. The ECU also monitors ride height and fault codes to determine when service is needed.

A compressor, reservoir, valves, and hoses adjust pressure to level, soften, or stiffen the ride.

Air springs / Airbags are a fundamental component of many air suspension systems.

Common Causes of the Service Ride Control Warning

You’ll often see the Service Ride Control warning when the air compressor is failing or overloaded, because the compressor can’t maintain required pressure for the air springs and the system flags a fault.

Leaks in air bags or air lines are another common cause, since even small leaks force the compressor to run continuously and can trigger overheating, reduced pressure, or error codes.

Inspecting compressor current draw, listening for constant run cycles, and performing a smoke or soapy-water leak test on bags and fittings will help you pinpoint whether the issue is compressor-related or due to leaks.

A failing compressor can also cause excessive electrical load that affects other components, including the starter motor, potentially leading to additional faults.

Compressor Failure or Overload

When the ride control compressor fails or becomes overloaded, the air suspension can’t maintain proper pressure and your vehicle will show symptoms like sagging corners, warning lights, or rough ride quality.

Compressor motors can overheat from continuous cycling, moisture can corrode components, and electrical faults—blown fuses, bad relays, poor grounds—can stop operation; test voltage, current draw, and sensors to diagnose.

Leaks in Air Bags

Leaks in air bags frequently cause the Service Ride Control warning because even small gaps or damage let pressurized air escape, preventing the suspension from holding the correct ride height.

You should inspect fittings, lines, and bag surfaces for punctures, jagged cuts, loose NPT threads, or corrosion.

Listen for hissing, watch for sagging, and replace or reseal damaged components promptly to restore integrity.

Symptoms That Signal Ride Control Problems

If your vehicle starts showing unusual cues like a warning lamp, a harsher-than-normal ride, or uneven tire wear, those signs often point to ride control problems that need prompt attention.

You may see an air ride suspension light, increased bouncing from worn shocks, steering instability from worn joints, or patchy tire wear indicating misalignment; each symptom guides targeted diagnostics.

Low battery voltage or faulty sensors can sometimes cause ride control warnings, so check the battery voltage and related systems.

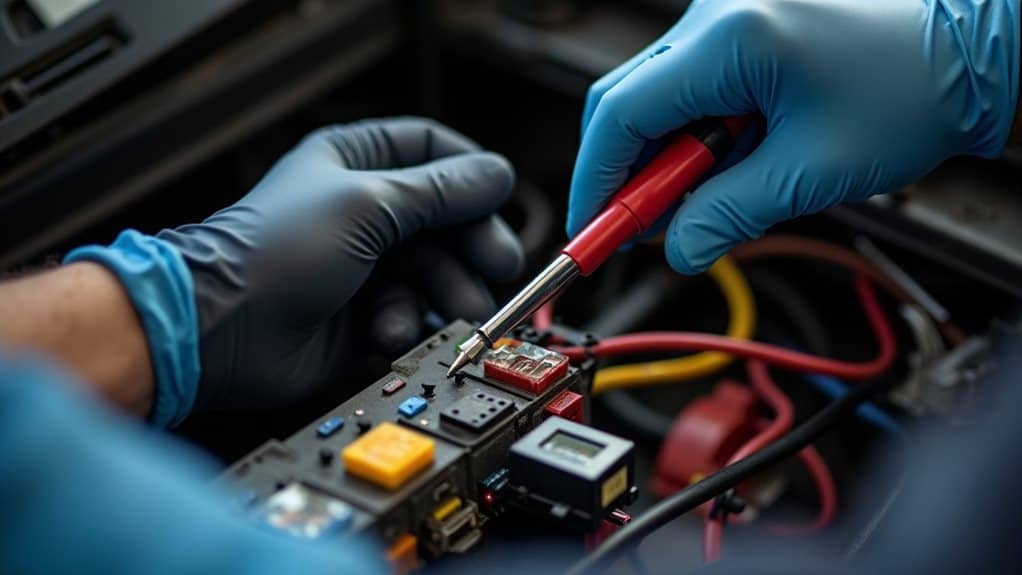

Inspecting Fuses, Wiring, and Electrical Components

Start by checking the fuses related to the ride control system, matching each fuse’s amperage to the vehicle specifications and looking for breaks, discoloration, or poor seating that can cause intermittent faults.

Then inspect the wiring loom visually and by feel for abrasion, cracked insulation, unauthorized splices, or routing too close to heat and moving parts, and use a multimeter to test continuity and resistance where damage is suspected.

Finally, examine terminals and connectors for corrosion or looseness, clean and tighten as needed, and document any non‑OEM repairs so you can restore proper circuit protection and reliable operation.

Check Related Fuses

When checking related fuses for a Service Ride Control warning, begin by locating and identifying each fuse and relay that supplies the suspension system, since multiple circuits (IGN3, Stud #1, RTD, compressor, and relay power fuses) protect different functions and a fault in any one can disable the system.

Inspect each fuse visually, then test with a multimeter or test light, check relay operation, and confirm terminals are clean and tight.

Inspect Wiring Harness

After you’ve checked the fuses and relays that feed the suspension system, inspect the wiring loom next, because many ride-control faults come from damaged or poorly connected wiring rather than blown fuses.

Examine the wiring bundle for frayed, exposed, kinked, or heat-damaged sections; check connectors for corrosion, loose pins, or poor crimps.

Perform wiggle, tug, continuity, and insulation tests to locate intermittent or hidden faults.

Checking the Air Compressor and Air Lines

Listen for the compressor and visually inspect the air lines before you begin any diagnostic work; the compressor supplies pressurized air to the suspension and the lines carry that air to the air springs, so both must be functioning properly for the system to hold height and ride quality.

Listen for motor noise, check electrical connections and mounting, measure pressure, inspect hoses, crimps, routing, and secure fittings.

Identifying Leaks and Damage in Air Bags and Shocks

Start by closely inspecting the air bags and shock absorbers for any signs of air or fluid loss, since small defects often cause larger failures if left unchecked.

Check for cuts, bulges, punctures, oily residue, rust, bent rods, or damaged fittings.

Note uneven ride height, tire wear, or excessive bounce, and verify mounts, bushings, and seals for cracks or looseness.

Diagnostic Tools and Fault Code Troubleshooting

You’ll plug diagnostic tools into the vehicle’s onboard computer to read live sensor data and stored fault codes, which gives you a direct window into the ride control system’s health.

Use OEM-level scan tools to read ABS, steering angle, suspension height codes, and real-time streams; compare sensor values to specs, identify intermittent faults, and clear codes after verifying repairs to confirm resolution.

Repair Options and When to Seek Professional Service

When suspension components show signs of wear or the ride control warning stays on, you’ll need to weigh repair options against safety and cost, since some fixes you can do yourself but others require a professional.

Replace failed air compressors, leaking air springs, or worn shocks; perform bushing and ball joint swaps, then computerized alignment. Seek pros for mounting damage, high-stress areas, persistent symptoms, or OEM-restricted repairs.

Wrapping Up

When your dashboard shows “Service Ride Control,” you should stop driving if the vehicle rides poorly or leans, and check systems promptly. Inspect fuses, wiring, air compressor function, and air lines for faults; look for visible leaks or damaged air springs and shocks. Scan for fault codes with an OBD-II or factory tool to pinpoint sensors or valves. Minor fixes you can handle; complex compressor or module repairs are best left to a trained technician.