When both front brake calipers won’t release, you’re typically facing seized pistons from corrosion buildup, stuck slide pins due to deteriorated grease, or internal brake hose blockages that trap hydraulic pressure like a one-way valve. Moisture-induced corrosion on moving parts, overheating from excessive braking, and improper caliper installation can also cause this dangerous condition. Neglecting regular brake fluid changes allows contamination that leads to piston sticking and seal degradation, creating continuous pad-to-rotor contact that generates excessive heat and reduces stopping power throughout your entire braking system.

Quick Tips

- Seized pistons from corrosion and rust buildup prevent normal retraction, causing continuous pad-to-rotor contact and brake dragging.

- Deteriorated caliper seals lead to fluid leaks and reduced hydraulic pressure, preventing proper piston retraction in both calipers.

- Corroded or stuck slide pins restrict caliper movement, creating uneven braking force and preventing proper brake release.

- Internal brake hose blockages act like one-way valves, trapping fluid and keeping calipers partially engaged with continuous drag.

- Overheating from excessive braking degrades brake fluid and seals, potentially causing caliper seizure and vapor lock issues.

Seized Pistons in Caliper Bores

When brake calipers fail to release properly, seized pistons represent one of the most common and problematic causes you’ll encounter.

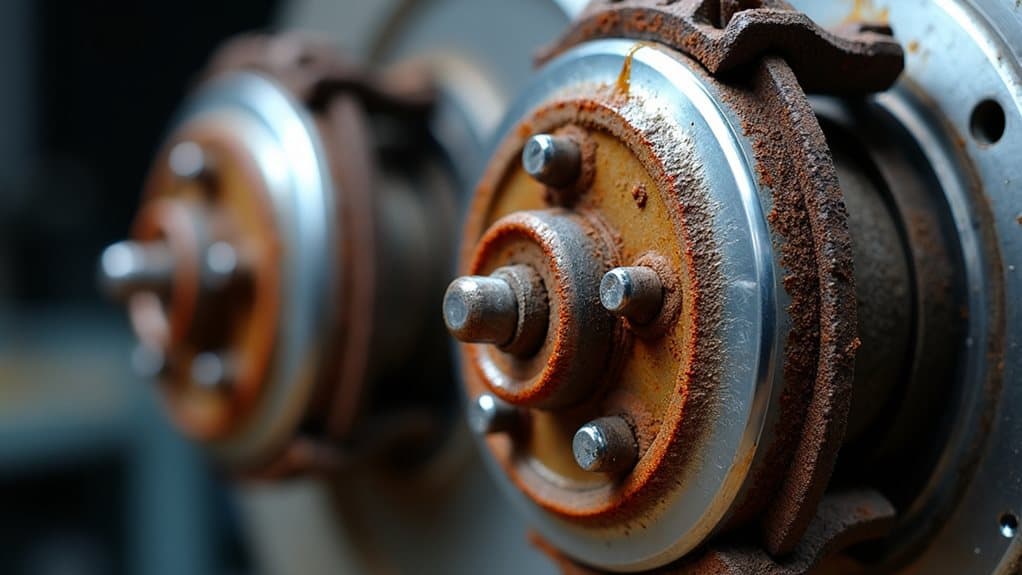

Corrosion and rust buildup inside the caliper bore restricts piston movement, preventing normal retraction after brake application. This creates constant pad-to-rotor contact, resulting in continuous dragging, overheating, and greatly reduced braking performance throughout your vehicle’s operation. Driving with a broken brake line can exacerbate these issues, leading to even more dangerous conditions.

Temperature fluctuations and exposure to the elements accelerate corrosion buildup in caliper pistons, making regular inspection essential for preventing complete brake failure.

Corroded or Stuck Slide Pins

While seized pistons often grab attention as the primary culprit behind brake caliper failures, corroded or stuck slide pins represent an equally troublesome issue that can compromise your vehicle’s braking performance.

These pins allow calipers to move freely during braking, but moisture, road salt, and inadequate lubrication cause rust formation that prevents proper sliding action. When slide pins become stuck or corroded, they create uneven braking force that can cause your vehicle to pull to one side during braking situations. Regular inspection of anti-rattle clips is essential to ensure optimal caliper function and prevent additional braking issues.

Internal Brake Hose Blockages

When internal brake hose blockages occur, you’ll experience significant fluid flow restriction that prevents brake fluid from moving freely through the system.

These blockages act like a one-way valve, allowing pressurized fluid to reach your calipers during braking but trapping that same fluid when you release the pedal.

This pressure retention issue keeps your front brake calipers partially engaged, creating the continuous drag that prevents proper caliper release. Additionally, regular inspection of battery connections can help identify underlying issues that may affect overall vehicle performance.

Fluid Flow Restriction

Although brake calipers receive hydraulic pressure through flexible brake hoses, these same hoses can become internal obstacles that prevent proper caliper release.

When rubber hoses deteriorate internally, they’ll swell and restrict fluid flow back to the primary cylinder. This restriction keeps your calipers partially engaged, creating persistent brake drag and heat buildup at both front wheels.

Pressure Retention Issues

As your brake system’s flexible hoses age and deteriorate, their internal rubber linings can collapse or balloon inward, creating restrictive blockages that function like one-way valves.

These obstructions allow pressurized fluid to reach your calipers but prevent its return flow, causing both front brakes to remain engaged.

You’ll need hose replacement, not caliper repair.

Damaged Brake Flex Hoses Trapping Pressure

While brake calipers often receive blame for sticking issues, damaged brake flex hoses frequently serve as the true culprit behind trapped pressure problems.

Internal hose collapse creates a one-way valve effect, allowing brake fluid to reach calipers under pedal pressure but preventing proper return flow.

This restriction keeps calipers partially engaged, causing continuous brake drag and premature pad wear. Regular inspections for brake fluid leaks can help identify such issues before they escalate.

Moisture-Induced Corrosion on Moving Parts

When moisture infiltrates your brake system, it triggers a cascade of corrosion that converts smooth-operating caliper components into seized, immovable parts.

Rust forms on caliper slides, pins, and pistons, creating friction that prevents normal retraction. This corrosion blocks vents and exhaust holes, impairing hydraulic function while causing your brake pads to drag continuously against the rotors.

Debris Accumulation in Caliper Assembly

When moisture penetrates your brake caliper assembly, it creates an entry pathway for road debris, brake dust, and metal particles that can seriously compromise your braking system’s performance.

You’ll find that damaged or deteriorated seals don’t just allow water in—they also permit dirt and grit to accumulate in critical areas like slide pin grooves, piston chambers, and guide channels where these contaminants restrict normal component movement.

This debris buildup prevents your calipers from moving freely, causing them to stick in the applied position and creating the frustrating situation where both front brake calipers won’t release properly after you’ve pressed the brake pedal.

Moisture and Dirt Entry

As brake calipers operate in harsh environmental conditions, moisture and dirt inevitably find their way into the caliper assembly through compromised seals and other entry points.

Once inside, these contaminants cause rust formation on pistons and slide pins, restricting their movement.

You’ll notice this contamination accelerates in areas with frequent road salt use during winter conditions.

Seal Damage Effects

The deterioration of caliper seals creates a cascade of mechanical problems that compound over time, ultimately leading to complete brake system failure.

When seals crack or tear, debris enters the caliper assembly, accumulating around the piston. This contamination restricts piston movement, causing brake pads to drag against rotors continuously, resulting in overheating, accelerated wear, and compromised stopping power.

Component Movement Restriction

Once contaminants breach the caliper assembly’s protective barriers, they create a mechanically destructive environment that systematically impairs every moving component within the brake system.

Dirt and debris accumulate around slide pins, causing them to seize and prevent proper caliper movement. This restriction forces brake pads to maintain continuous contact with rotors, creating excessive heat and premature wear.

Deteriorated Brake Caliper Seals

Brake caliper seals represent one of the most critical yet vulnerable components in your vehicle’s braking system, and their deterioration stands as a primary cause when both front brake calipers fail to release properly.

These rubber seals degrade from heat, moisture, and road contaminants like salt, causing fluid leaks that reduce hydraulic pressure and prevent proper piston retraction.

Dried Out Slide Pin Lubricants

When brake caliper slide pins don’t receive proper lubrication maintenance, the grease gradually breaks down from heat cycles and environmental exposure, creating a sticky residue that prevents smooth caliper movement.

This deteriorated lubricant increases friction between the slide pins and their housing, causing the pins to seize and preventing your calipers from floating properly as the brake pads wear.

You’ll need to remove the old dried lubricant completely and apply fresh dielectric grease during regular brake maintenance to restore proper caliper function and prevent both calipers from binding.

Lubricant Degradation Over Time

As your vehicle accumulates miles and years of service, the specialized lubricants protecting your brake caliper slide pins inevitably deteriorate, creating one of the most common yet overlooked causes of caliper binding.

Extended exposure to high temperatures accelerates grease oxidation and drying, while moisture ingress leads to rust and contamination, compromising lubricant integrity completely.

Increased Friction and Seizing

Deteriorated lubricants create a cascade of mechanical problems that convert your brake calipers from smoothly operating components into sources of dangerous friction and binding.

Dried grease causes slide pins to seize, preventing lateral caliper movement. This sticking creates uneven brake pad wear, rotor overheating, and brake judder.

Metal-to-metal contact increases corrosion risk and compromises braking safety.

Replacement and Maintenance Requirements

Once slide pin lubricants deteriorate beyond their functional capacity, you’ll need to address the problem through systematic replacement and maintenance procedures.

Remove caliper mounting bolts, then clean pins thoroughly to eliminate dried grease and corrosion.

Apply brake-specific silicone lubricant evenly, reinstall components carefully, and test caliper movement to confirm proper sliding function.

Overheating From Excessive Braking

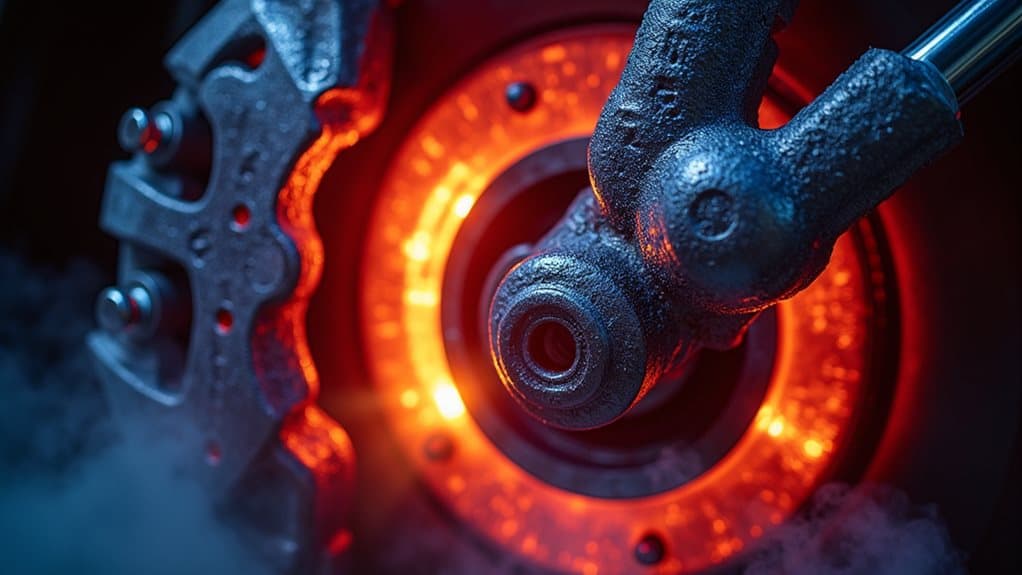

When your front brake calipers refuse to release, overheating from excessive braking often serves as the primary culprit behind this dangerous malfunction.

Aggressive braking generates excessive heat, while prolonged brake application during downhill driving creates sustained heat buildup.

This continuous friction prevents proper cooling periods, causing brake fluid degradation and caliper seizure.

Thermal Damage to Brake Components

Although overheating creates the initial problem, the thermal damage that follows converts a temporary brake issue into permanent component failure.

Excessive heat warps your brake discs through uneven thermal expansion, while high temperatures degrade caliper seals and cause brake fluid to boil.

This creates vapor lock, reducing hydraulic pressure and making your brake pedal feel spongy.

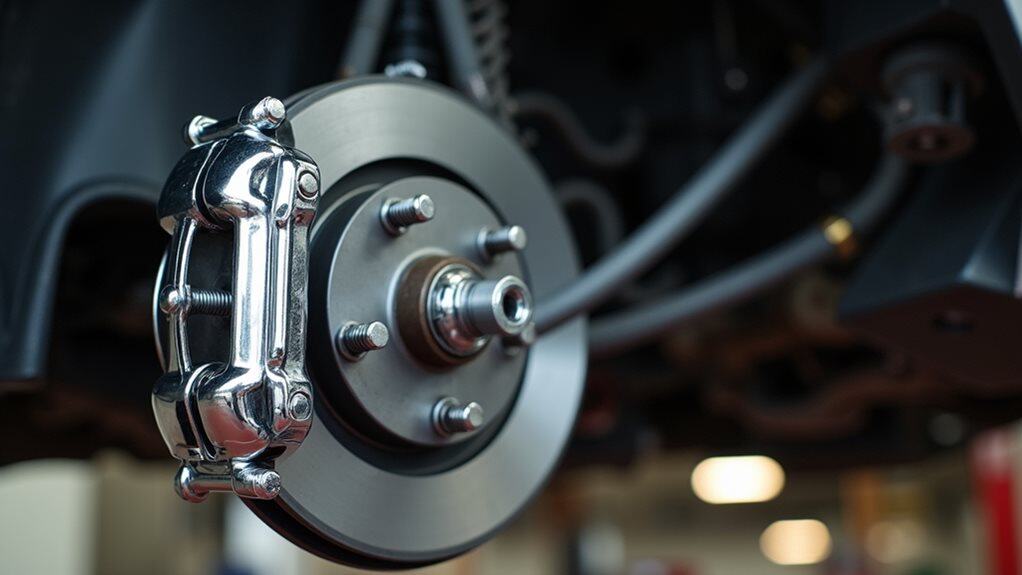

Improper Caliper Installation Alignment

While thermal damage represents a gradual deterioration of brake components, improper caliper installation alignment creates immediate problems that can affect both front brake calipers simultaneously.

You’ll notice symptoms like persistent rubbing noises, uneven pad wear, and vehicle pulling during braking.

Misaligned calipers cause constant pad contact with rotors, preventing proper release and reducing stopping power considerably.

Inadequate Brake System Maintenance

Beyond installation errors, inadequate brake system maintenance stands as one of the most preventable causes of both front brake calipers failing to release properly.

When you neglect regular brake fluid changes, contaminated fluid causes caliper pistons to stick.

Additionally, accumulated brake dust and debris prevent proper caliper movement, while worn components create excessive heat that damages seals.

Wrapping Up

When both front brake calipers won’t release, you’re dealing with multiple system failures that demand immediate attention. Don’t attempt repairs unless you’re experienced with brake systems, as improper work creates serious safety hazards. Start by checking brake fluid levels and inspecting hoses for visible damage. If you can’t identify obvious problems, take your vehicle to a qualified mechanic immediately. Driving with stuck calipers risks brake failure, overheating, and potential accidents.