To bypass a TBI fuel pump relay in an emergency, you’ll need to locate the relay in your vehicle’s fuse box and identify pins 30 and 87. After removing the relay, connect these pins using a jumper wire while wearing safety gear. Listen for the fuel pump’s hum when turning the ignition to “ON” position. This temporary solution can get your engine running, but proper safety precautions and testing are vital for successful implementation. Understanding the complete process guarantees you’ll handle this repair confidently.

Quick Tips

- Locate the fuel pump relay in your vehicle’s fuse box and remove it carefully, referring to the owner’s manual for exact position.

- Connect pins 30 and 87 using a red jumper wire while wearing safety gear to create a temporary power circuit.

- Listen for the fuel pump’s humming sound when turning the key to verify successful bypass connection.

- Secure all wire connections with electrical tape to prevent shorts and ensure consistent power flow during startup.

- Test the engine start while monitoring for proper fuel pressure and unusual sounds, keeping a fire extinguisher nearby.

Understanding the TBI Fuel Pump Relay System

Five key components work together in a TBI (Throttle Body Injection) fuel pump relay system to guarantee your engine receives the fuel it needs.

Your ECM controls the relay, which acts as an electromagnetic switch managing power to the fuel pump. When you turn your key, the system activates briefly, and once your engine’s running, redundant circuits maintain consistent fuel delivery through the filter. Electrical issues can disrupt this process and lead to poor engine performance that often results from relay problems.

Regular inspections help prevent poor engine performance that often results from relay problems.

Essential Tools and Safety Equipment

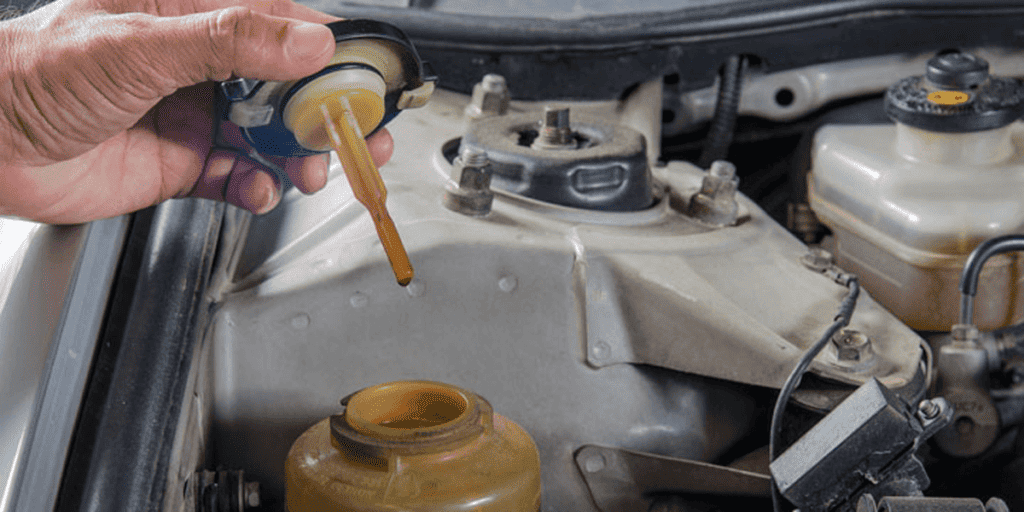

Before attempting any TBI fuel pump relay bypass, you’ll need to gather specific tools and safety equipment to guarantee a successful and hazard-free repair.

Your essential items include a multimeter for testing circuits, wire cutters, jumper wires, and electrical tape. A red jumper wire for direct power connection to the fuel pump can be critical for emergency situations. Additionally, remember that acetone, being flammable, can pose risks in poorly ventilated areas, so ensure you’re working in a safe environment.

Don’t forget your safety gear: goggles, gloves, and a fire extinguisher, while ensuring you’re working in a well-ventilated space.

Locating and Accessing Your Fuel Pump Relay

You’ll find your vehicle’s fuel pump relay in the fuse box, which is typically located under the hood in the engine bay or near the steering column.

Once you’ve opened the fuse box cover, you can identify the fuel pump relay by looking for a rectangular or square-shaped component labeled with “fuel pump” or by consulting your vehicle’s manual for the specific relay position.

To access the relay, you’ll need to carefully remove any protective covers or obstacles, keeping track of their positions for reassembly later. Ensure you understand the fuel pump wiring color codes to avoid any mistakes while working on the relay.

Fuse Box Access Points

Locating the fuel pump relay in your vehicle begins with finding the correct fuse box, which is typically mounted in one of several standard locations.

You’ll most commonly find it under the hood near the battery or along the sides of the engine compartment.

Check your owner’s manual or look for a diagram on the fuse box cover that’ll help you identify the exact position of the fuel pump relay.

Relay Identification Methods

Once you’ve accessed the fuse box, identifying your vehicle’s fuel pump relay requires a systematic approach using several reliable methods.

You’ll find it’s typically a cube-shaped component with prongs, often labeled with a diagram. Check your owner’s manual for exact location details, and listen for a distinct clicking sound when turning the ignition.

For thorough verification, use a multimeter to test functionality.

Step-by-Step Bypass Instructions

Before attempting a fuel pump relay bypass, gathering the necessary tools and understanding the safety precautions is essential for a successful procedure.

First, locate and remove the relay from your fuse box. Then identify pins 30 and 87.

Using jumper wires, carefully connect these pins while wearing protective gear. You’ll need to secure all connections with electrical tape to prevent shorts. Additionally, ensure that the battery voltage is adequate, as battery issues can also affect the starting process.

Testing the Temporary Bypass Setup

Three essential tests must be performed when verifying your temporary fuel pump relay bypass setup.

First, listen for the pump’s humming sound when you turn the ignition to “ON.”

Next, check the fuel pressure using your test gauge.

Finally, start the engine and monitor its performance while ensuring there aren’t any fuel leaks around your bypass connections.

Common Troubleshooting Issues

When troubleshooting TBI fuel pump relay issues, you’ll likely encounter several common problems that can affect your vehicle’s performance.

Power supply issues from your battery or faulty wiring can prevent proper relay activation.

You’ll also need to watch for grounding problems, which often cause erratic fuel system behavior.

If you notice sensor malfunctions, particularly with the oil pressure sensor, these can disrupt normal fuel pump operation.

Important Safety Warnings and Precautions

Before starting any fuel pump relay bypass work, you’ll need to gather essential protective equipment including safety goggles, gloves, and a fire extinguisher.

Fire prevention is critical, so make certain you’re working in a well-ventilated area away from any flammable materials or open flames.

Since you’re dealing with electrical components near fuel systems, it’s essential to disconnect the battery and keep your workspace clean and dry to prevent potential fires or electrical hazards.

Fire Prevention Guidelines

Since working with fuel systems carries inherent fire risks, implementing thorough fire safety measures isn’t just recommended – it’s absolutely vital.

Keep a fire extinguisher rated for fuel fires nearby, guarantee your work area is well-ventilated, and remove all potential ignition sources.

You’ll need to inspect your equipment regularly and maintain clear access to emergency exits while working.

Essential Protective Equipment

Proper protective equipment stands as the foundation of any safe fuel pump relay bypass procedure.

You’ll need insulated tools and gloves to protect against electrical shock, while safety goggles shield your eyes from sparks.

Keep a multimeter or test light handy to verify connections, and don’t forget your wire cutters and strippers for proper wire preparation.

Wrapping Up

While bypassing your TBI fuel pump relay can get you back on the road during an emergency, it’s essential to treat this as a temporary fix only. You’ll need to properly diagnose and repair the underlying issue as soon as possible to prevent potential safety hazards or further damage to your vehicle’s electrical system. Remember to disconnect your bypass setup once you’ve reached a safe location, and consult a qualified mechanic for permanent repairs.