If you hear a rubbing noise from the front wheel while driving, it’s usually a mechanical contact issue: worn wheel bearings or a loose hub will hum or grind, stuck calipers or seized slide pins keep pads touching rotors, and warped or scored rotors create metal-on-metal scraping; bent dust shields or trapped debris can intermittently rub the rotor, and torn CV boots, suspension wear, or misalignment change noise when turning—inspect wheel play, spin the wheel, and check brakes, hubs, and shields to find the cause and learn how to fix it.

Quick Tips

- Worn or failing wheel bearings produce grinding or humming that changes with speed and when turning.

- Brake issues (stuck caliper, worn pads, or scored rotors) cause constant rubbing, squeal, or metal-on-metal grinding.

- Bent dust shield or backing plate can intermittently contact the rotor, creating scraping or high-pitched noise.

- Debris (stones, rust flakes) trapped between rotor and shield produces persistent grinding and rotor scoring.

- Suspension, steering, or CV joint problems can cause rubbing, clicking, or noise changes when turning or under load.

Common Wheel Bearing Problems Causing Rubbing Noises

When you hear a rubbing or grinding noise from a front wheel, the wheel bearing is a common culprit and it’s important to understand the specific problems that cause those sounds.

You’ll encounter loss of lubrication, contamination from water or debris, hub looseness causing misalignment, impact damage from potholes, and higher torque stress in heavier or electric vehicles; each condition accelerates metal-on-metal wear. Wheel bearings support the vehicle’s weight and allow wheels to rotate with minimal friction. Regular inspections can detect early warning signs like unusual noises and vibrations that indicate bearing wear inspection schedule.

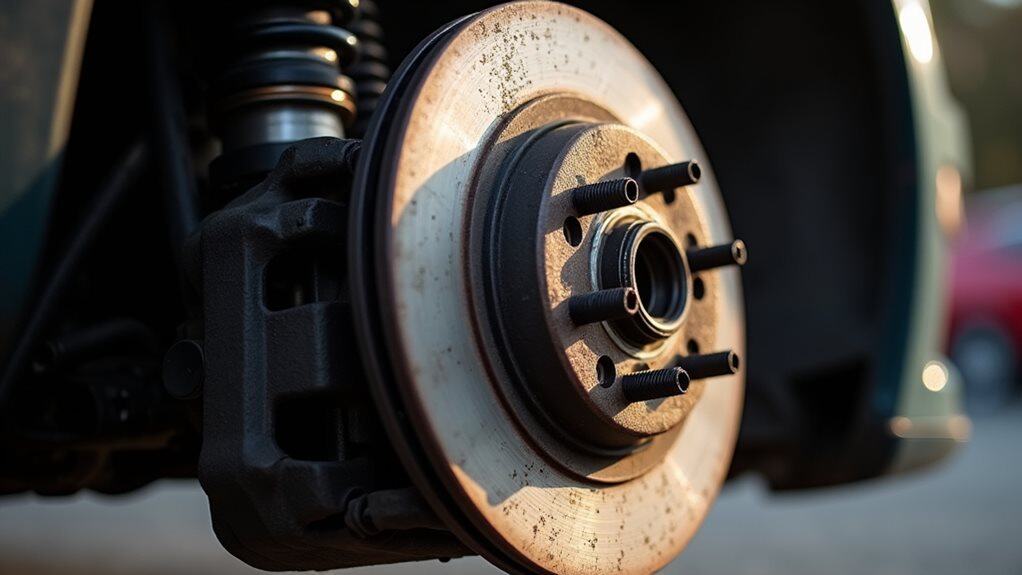

Brake Pad and Rotor Issues That Lead to Grinding

Listen for differences between simple squeaks and a true grinding sound, because brake pad and rotor issues are among the most common causes of front-wheel rubbing noises and they require prompt attention.

Worn pads expose metal backing plates that scrape rotors, causing grinding. Scored or warped rotors and trapped debris or contaminated pads also produce metal-on-metal noise and reduced braking effectiveness. Regular inspections can catch pad wear and rotor damage before grinding leads to more serious safety and repair costs. Proper maintenance also includes periodically checking brake fluid and bleeding brakes after caliper replacement to ensure safe, responsive braking.

Caliper Seizure and Sticking Components

Check the caliper area if you hear a rubbing noise, because stuck caliper pistons can keep brake pads partially pressed against the rotor, causing constant contact and heat.

Seized slide pins or jammed brake hardware prevent the caliper from moving freely, which leads to uneven pad wear and squealing or grinding sounds; inspect and clean the pins, lubricate with high-temperature brake grease, and replace corroded components.

If piston seals or mounting hardware are damaged or heavily corroded, replace the caliper or affected parts to restore proper retraction and safe braking performance.

Using penetrating spray and letting it soak can help free corroded parts and bolts, especially when combined with an impact gun or extraction tools for stubborn fasteners.

Stuck Caliper Pistons

A seized or sticking caliper piston happens when the round piston inside the brake caliper can’t slide back and forth freely, and that restriction lets a pad rub the rotor almost constantly.

You’ll notice pulling to one side, hot wheels or a burning smell, rapid inner pad wear, and altered pedal feel.

Inspect for leaks, debris, corroded seals, and change brake fluid regularly to prevent seizure.

Seized Slide Pins

Seized slide pins occur when the metal guide pins that let a brake caliper move laterally become corroded, contaminated, or insufficiently lubricated, and they stop allowing the caliper to float freely over the rotor.

You’ll notice pulling during braking, uneven inner pad wear, squeal or drag, and higher fuel use; inspect, clean, replace boots, and apply approved high‑temp grease to restore smooth sliding.

Jammed Brake Hardware

When a brake caliper or its internal components jam, the piston and sliding surfaces can stop moving freely and the result is persistent pad contact with the rotor; this produces dragging, uneven braking, and accelerated wear.

You’ll notice pulling, burning smells, or reduced acceleration.

Clean, lubricate, inspect seals and guide pins; replace corroded pistons or the entire caliper if leaks, heavy corrosion, or seized parts remain.

Damaged or Bent Brake Dust Shields and Backing Plates

Check the brake dust shield behind the rotor if you hear a scraping sound, because shield-to-rotor contact is a common cause of rubbing noises and you’ll often see shiny contact marks where metal meets metal.

A bent backing plate edge can flex inward when you turn or hit a bump, intermittently touching the rotor and producing a metallic brushing or clanking noise that changes with speed and steering.

You can usually straighten minor bends carefully with hand tools to restore clearance, but replace heavily corroded or badly deformed shields to prevent rotor wear and reduced braking performance.

Also inspect and replace worn anti-rattle clips as needed to prevent excessive pad movement and noise.

Shield-To-Rotor Contact

Because brake dust shields sit only a few millimeters behind the rotor, even small bends, corrosion, or trapped debris can cause the shield to rub the rotor and make a high-pitched screech or scraping noise.

You should inspect for rusted edges, inward folds, or lodged pebbles by removing the wheel and spinning it; gently bend or replace shields, clean debris, and prevent recurrence.

Bent Backing Plate Edge

If a backing plate or brake dust shield gets bent or corroded, it can press against the rotor or other moving parts and cause persistent scraping or rubbing noises while you drive.

You should inspect for bends, rust, or contact points; damaged edges often touch rotors, creating metallic scraping.

Repair options include trimming the lip carefully or replacing the plate to restore clearance and prevent rotor or pad damage.

Debris and Foreign Objects Trapped in the Wheel Assembly

Debris trapped in the wheel assembly can cause a range of rubbing noises and damage, so you’ll want to understand where particles get in and how they affect components; small stones or gravel can wedge between the brake rotor and pads producing grinding or squealing, while rust flakes and metal fragments from corroded parts create continuous rubbing or scoring sounds.

Inspect wheel wells, hubs, calipers, seals, and bearings for stones, leaves, sand, and metal shards; remove contaminants, replace scored rotors or pads, and repair seals to prevent bearing contamination and uneven wear that causes vibration, reduced braking performance, and persistent noise.

CV Joint and Axle-Related Noises When Turning

Listen for distinct clicking, popping, or rhythmic knocking when you turn the wheel, because those sounds often point to worn CV (constant-velocity) joints or a damaged axle rather than brakes or wheel bearings.

If boots are torn, grease leaks and contaminants accelerate wear, causing clicks at low speeds, vibrations at higher speeds, and progressive knocking; catch leaks early to repair boots or replace joints before axle failure.

Suspension and Wheel Alignment Effects on Rubbing Sounds

When suspension parts aren’t installed correctly or start to wear, they can make rubbing or groaning noises that you can both hear and feel through the steering, especially during turns or over bumps.

Check upper strut mounts, spring caps, control arm bushings and wheel bearings; misfit caps or dry bushings rub, misalignment stresses bearings, and correcting installation plus proper alignment and lubrication usually stops the noise.

Lack of Lubrication and Seal Failures in Hubs

If wheel seals fail and grease starts escaping the hub, you’ll quickly notice both visible residue and changes in how the wheel behaves; seals are designed to keep bearing lubricant in place and contaminants out, so any breach lets grease fling onto nearby components while dirt and water enter the bearing area.

Loss of lubrication raises friction, creates grinding or humming noises, and accelerates bearing wear, risking play, corrosion, and eventual failure.

Diagnostic Steps to Pinpoint the Source of Front-Wheel Rubbing

Because front-wheel rubbing can come from several systems at once, you’ll want to follow a structured diagnostic sequence that narrows the cause quickly and safely.

Drive at moderate speed, note sound changes when turning, then inspect tires for wear, debris, and spin wheels by hand.

Check wheel play, bearings, suspension, steering, brake pads, rotors, dust shields, and use a stethoscope to localize noise.

Wrapping Up

You can usually find and fix a rubbing noise by systematically checking bearing wear, brake components, dust shields, trapped debris, CV joints, suspension alignment, and hub lubrication; start with a visual inspection, then lift the wheel to spin and feel for play, brake drag, or roughness, and use a wrench and stethoscope to isolate sounds. If you’re unsure or see severe damage, consult a qualified mechanic to avoid safety risks and prevent further component failure.